Ever walked past an old barn on the edge of your property and thought, “What if that could be a cosy living space instead of just a storage shed?”

That flicker of possibility is the first spark behind every barn conversion cost discussion – because before you can dream about open‑plan lofts, you need to know what the numbers actually look like.

In our experience, the biggest surprise isn’t the price tag itself, but the mix of hidden costs that pop up once the roof is stripped and the concrete slab is laid. You’ll hear terms like site access, 4×4 vehicle logistics, heritage approvals and storm‑water management, all of which can add a few thousand dollars to the base estimate.

So, what does a typical barn conversion cost in rural NSW? A rough baseline for a modest 150‑square‑metre project starts around $120,000, covering structural reinforcement, insulation, cladding and basic interior finishes. Add on specialised items – say, a timber‑beam ceiling, double‑glazed windows or a modern kitchen – and you’re looking at $150,000 to $180,000.

But here’s the thing: every farm is different. A barn tucked behind a gravel track in the New England region will demand extra fuel, tyre wear and perhaps a portable generator for power. That logistical tail‑end can easily tack on $5,000‑$10,000. Meanwhile, a larger outbuilding on a flat site near Dubbo may shave a few thousand off because the crew can drive straight in.

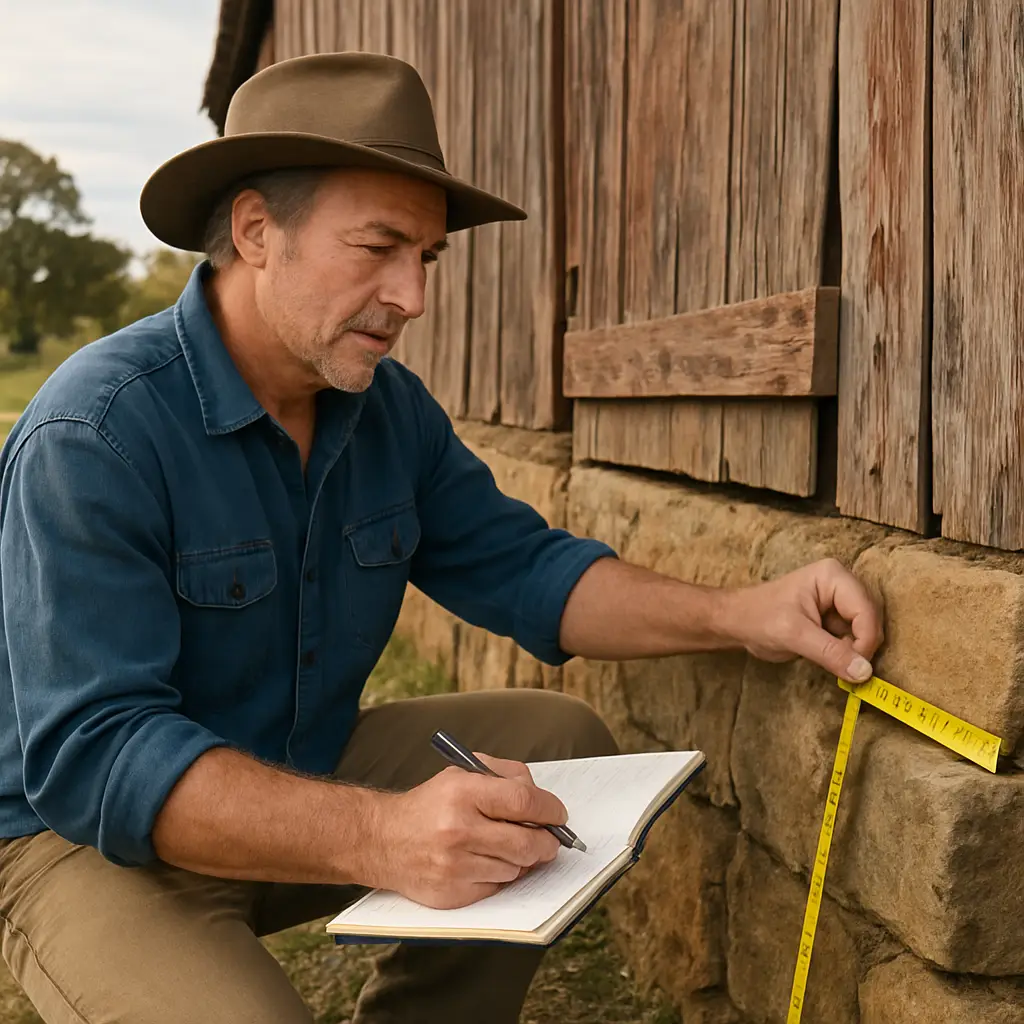

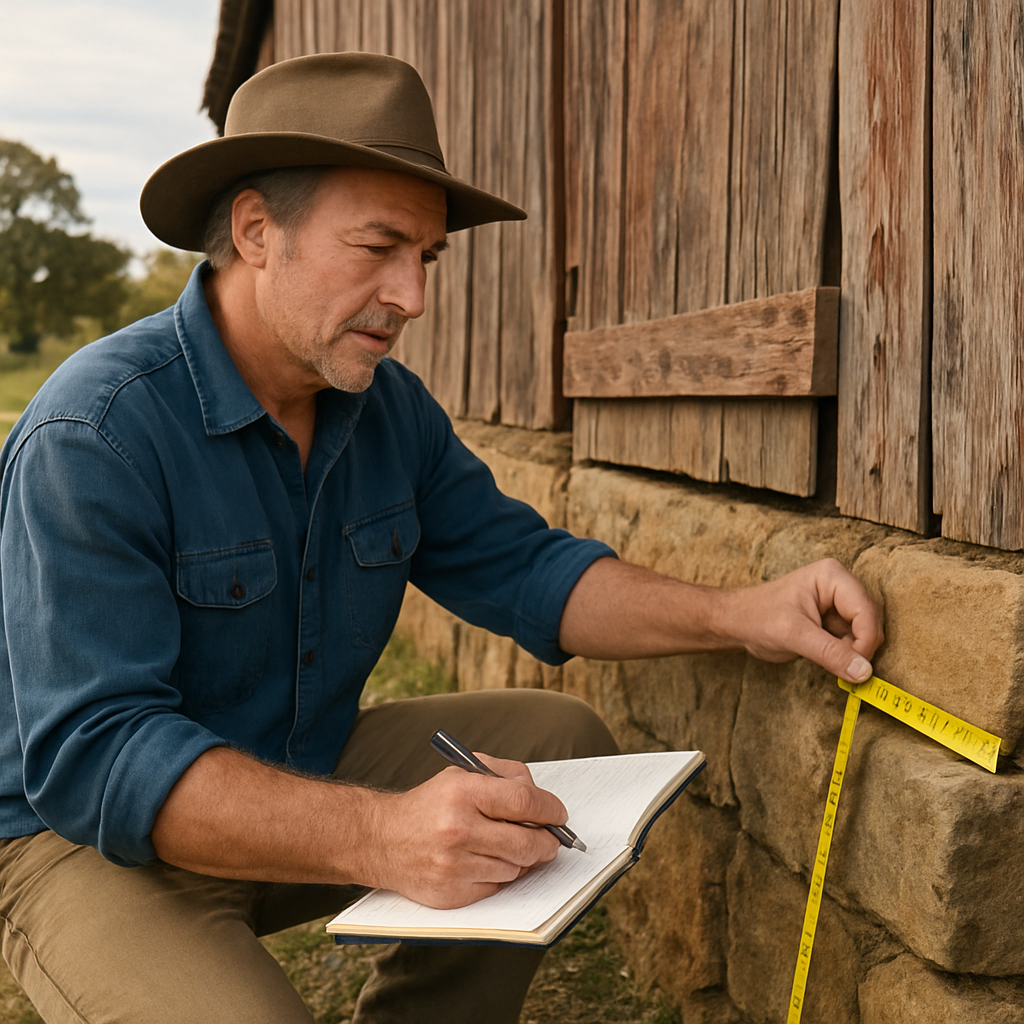

What helps most is a clear, on‑site assessment before any quote is handed over. We always start with a walk‑around, checking foundation health, roof condition and how the building ties into existing fences or livestock yards. That way you avoid nasty surprises once the demolition hammer starts swinging.

Ready to get a realistic picture of your barn conversion cost? The next step is simple – reach out for a no‑obligation site visit. We’ll map out the scope, flag any hidden expenses and give you a line‑item estimate you can actually work with.

Let’s turn that weathered barn into a place you’ll actually want to spend evenings in.

TL;DR

Barn conversion cost typically starts around $120,000 for basic structural work, climbs to $150‑180k with finishes, and can add $5‑10k more for remote‑site logistics like extra fuel and 4×4 access.

We recommend a free on‑site assessment with Awesim Building Contractors to produce a detailed, line‑item quote that saves you from hidden surprises and keeps your project on budget.

Step 1: Assessing Existing Structure and Planning Budget

First thing’s first – walk up to that old barn and take a good look. What you’re really doing is asking yourself, “Is this frame still solid enough to hold a loft, or am I looking at a costly rebuild?” That moment of recognition is where the budget story begins.

Grab a flashlight, a notepad, and a sturdy pair of boots. In our experience, the most common surprise is hidden rot in the timber or a cracked footings slab that the owner never noticed because the roof was still intact. Spot those issues early and you’ll save thousands later.

Here’s a quick checklist we use on site:

- Inspect roof trusses for split or insect damage.

- Check the condition of the sill plates and any existing insulation.

- Look for moisture stains on interior walls – they often point to roof leaks.

- Assess the foundation: are the concrete footings cracked, or is the soil shifting?

Once you’ve got your notes, it’s time to translate them into numbers. Start with a rough line‑item list: structural reinforcement, new roof, insulation, flooring, and any specialist work like timber‑beam restoration. Add a contingency of 10‑15% for the unknowns – that’s the safety net for remote‑site logistics, fuel, and 4×4 haulage costs.

Speaking of haulage, getting heavy timber or steel beams to a farm on a gravel track isn’t cheap. That’s where a reliable hitch comes in. The ProPride 3P® Jim Hensley Hitch is a favourite among NSW farmers for its stability on rough terrain, and it can make moving those big beams a lot less stressful (and costly).

Now, let’s talk money. A baseline barn conversion cost in rural NSW starts around $120,000 for the basics – think structural work and a simple interior finish. If you’re adding custom features like reclaimed timber cladding or high‑end kitchen appliances, you’ll be looking at $150,000‑$180,000. Remember to factor in extra fuel and tyre wear if the site is more than 30km off a sealed road – that can add $5,000‑$10,000.

One way to keep the numbers realistic is to pull a practical guide to farm renovation budgeting into your planning. It walks you through how to break down each cost centre and what to ask your builder during the quote stage.

Don’t forget the finishing touches. Windows and shutters may seem decorative, but they’re part of the overall cost equation. Quality shutters can improve energy efficiency and protect against dust storms. The Monroe Plantation Shutter Pros offer custom options that fit the aesthetic of a converted barn while staying within budget.

Below is a short video that shows a typical on‑site assessment – it walks you through the same steps we just outlined, so you can visualise the process.

After watching, you’ll have a clearer picture of what to expect and how to talk numbers with a builder.

Finally, sit down with your notes and draft a simple spreadsheet. Columns for “Item”, “Estimated Cost”, “Contingency”, and “Notes” keep everything transparent. When you hand this to a contractor, you’ll be able to spot any surprise line items instantly.

Bottom line: a solid assessment saves you from budget blow‑outs later. It’s the first step to turning that weathered barn into a warm, livable space you’ll actually want to spend evenings in.

Step 2: Securing Permits and Understanding Regulations

So you’ve walked the barn, jotted down every crack and timber, and you’re feeling the buzz of a possible new living space. But before you start ordering steel joists, there’s a paperwork mountain called “permits” that can either smooth the road or send you back to the drawing board.

In our experience, skipping the permit stage is the quickest way to see your barn conversion cost balloon – unexpected fees, stop‑work orders, or even having to undo work that’s already been done. Does that sound like a nightmare? It doesn’t have to be, if you treat the process like a checklist rather than a mystery.

Know your council’s playbook

Every shire or regional council in NSW has its own set of forms, fees, and timelines. The first thing you should do is pop onto your local council website (or give them a call) and ask for the “Barn Conversion” or “Change of Use” guidelines. Look for:

- Zoning classification – is your property in a “Rural” zone that allows residential conversions?

- Set‑back and height restrictions – how far must the new walls sit from the property line?

- Storm‑water management requirements – will you need a new drainage plan?

Getting these answers early means you can factor any extra excavation or drainage work into your barn conversion cost right now, rather than later.

Heritage and environmental checks

Many older barns sit on heritage‑listed land, especially in historic towns like Armidale or Gunnedah. If your barn has a heritage plaque, you’ll need a heritage impact statement and possibly a specialised architect’s report. Even if it isn’t listed, a quick search on the NSW Heritage Register is worth the five‑minute scroll.

Environmental concerns can also creep in – think about wetlands, native vegetation, or protected fauna. A simple environmental assessment, usually $300‑$600, can save you from a $5‑$10k surprise if the council flags an issue after you’ve already broken ground.

Building certifier and construction certificate

In NSW you must engage a licensed building certifier to prepare a Development Application (DA) and, once approved, issue a Construction Certificate (CC). The certifier checks that your plans meet the Building Code of Australia, structural standards, and any council conditions.

Tip: Ask the certifier if they offer a “fast‑track” DA service – it can shave two‑to‑three weeks off a typical 6‑week timeline, which is priceless when you’re juggling crop seasons or livestock movements.

Step‑by‑step permit checklist

Here’s a quick, no‑fluff list you can copy into a spreadsheet today:

- Confirm zoning – pull the council zoning map for your lot.

- Gather existing plans – any old building approvals, structural drawings, or heritage reports.

- Engage a licensed building certifier.

- Prepare and submit the Development Application (DA) with plans, site photos, and any heritage/environmental statements.

- Pay council fees (usually 0.5‑1% of total project cost) and any specialist report costs.

- Once DA is approved, obtain the Construction Certificate (CC) from your certifier.

- Schedule a pre‑construction meeting with council building officers to walk the site.

- Keep a copy of all approvals on site – inspectors love to see them.

Once those boxes are ticked, you’ll have a clear line‑item for permit fees, which you can roll into your overall barn conversion cost budget.

Now, a word on timing. Rural councils can be slower during the harvest season, so aim to submit your DA at least eight weeks before you plan to start construction. If you’re on a remote property where our 4×4 crew can’t easily haul heavy paperwork, we can bring a portable printer and submit the forms in person – a small extra cost that keeps the project moving.

Finally, remember that every approved permit is a safety net. It protects you, your builder, and your investment. When the council signs off, you’ll know the barn conversion cost you’ve budgeted is realistic, compliant, and ready for the next step – the actual build.

Ready to take the next step? Grab a pen, open a new document, and start ticking those checklist items. The sooner you lock in the permits, the sooner you’ll be watching those beams go up, not the council emails pile up.

Step 3: Choosing Materials and Finishes for Rural Aesthetics

Now that you’ve got the permits sorted, the next big question is what the walls, roof and floor will actually look like – and how that choice will shape your overall barn conversion cost.

Think about climate first, then cladding

Out here in New South Wales the weather can swing from scorching summer heat to frosty winter nights. That means you want a cladding system that breathes but also keeps the cold out. Many of our clients in Armidale end up with a mix of colour‑stained timber and metal siding – the timber gives that warm, country feel, while the metal acts like a weather‑proof shield.

If you’re after a low‑maintenance option, metal composite roofing panels are worth a look. Builders on the BuildHub forum share how a 137 mm insulated panel can deliver a U‑value around 0.13, cutting both heating bills and the need for interior plasterboard 【1】.

Insulation and thermal bridges – the hidden cost drivers

It’s tempting to slap a blanket of fibreglass between the studs and call it a day, but without a proper thermal break you’ll see condensation creep in during a cold snap. In our experience wrapping the steel columns in closed‑cell spray foam – or even a simple Celotex wrap – saves you from future water damage and a few thousand dollars in repairs.

Remember the floor: raising the slab a few hundred millimetres and filling the void with hardcore, blinding and a vapour‑control membrane adds upfront cost, but it slashes long‑term heating expenses. A modest 200 mm layer of rigid board under the slab can shave $2‑$3k off the total barn conversion cost.

Flooring and interior finishes that fit the rural vibe

Concrete is sturdy, but it feels cold under bare feet. A popular trick is to lay reclaimed timber decking over a sleeper system – you get that rustic look and a warm surface without the price tag of a full‑size timber floor.

For walls, board‑up the interior with board‑type plasterboard or, if you love the industrial edge, leave the steel ribs exposed and paint them with a rust‑inhibiting primer. The latter can save you the cost of a finish coat and still look intentional.

Colour, texture, and curb appeal

Don’t underestimate the power of a well‑chosen colour palette. Earthy ochres, muted greys and deep greens blend with the surrounding landscape, meaning you won’t need expensive landscaping later on.

Texture matters too. A simple line‑studding on the exterior gives depth, while a reclaimed metal roof – the kind WeatherCheck recommends for harsh climates – adds durability and visual interest 【2】.

Cost‑saving tips you can act on today

- Source locally milled timber; shipping fees can add $1‑$2k.

- Buy insulated metal panels in bulk; many suppliers offer a 5 % discount for orders over 30 sq m.

- Reuse existing roof trusses where they’re still sound – you’ll cut structural steel costs by up to 15 %.

- Combine finish work: a single coat of high‑quality exterior paint can double as a protective seal for both timber and metal.

- Plan for a DIY finish on non‑structural walls – a weekend of sanding and staining can save $1‑$2k.

Bottom line: every material choice nudges the barn conversion cost up or down, but the sweet spot is where durability meets the look you love. Sketch out a quick material board, compare the upfront price with the long‑term maintenance savings, and you’ll end up with a space that feels like home without breaking the bank.

Step 4: Detailed Cost Breakdown and Budget Allocation

Let me be completely honest: the difference between a quote and the final barn conversion cost is almost always the line‑items you didn’t list at the start.

So let’s fix that. Below is a step‑by‑step way to turn a vague budget into a working, day‑by‑day cash plan you can actually use on a rural site.

1. Start with a clear line‑item spreadsheet

Open a fresh spreadsheet and create columns for: item, quantity/area, unit cost, supplier/quote, and timing. Keep a notes column for the “why” — e.g., heritage approval required or 4×4 access for deliveries.

Why does this matter? Because small decisions — insulated panels vs single skin, or reuse of trusses — change the barn conversion cost by thousands. Tracking them avoids surprise budget drift.

2. Major cost buckets and realistic ranges

Break the budget into predictable buckets: demolition & waste, foundations/slab, structural reinforcement, roof & cladding, insulation & thermal work, joinery & finishes, services (electrical/plumbing), logistics, permit fees, and contingency.

Here’s a practical example from recent rural work: on a 150 m² conversion we saw roof + cladding take 18–25% of the build, structural works 20–30%, services 12–18%, finishes 20–25%, and logistics/remote access 3–7%.

So, what should you do next? Allocate the big chunks first, then refine the smaller items.

3. Practical budgeting steps you can do this afternoon

Step 1: Walk the barn and measure. Note the roof area and slab footprint.

Step 2: Get three quotes for each major item. For example, two roofers, one structural engineer, two electricians.

Step 3: Price the logistics. If the delivery truck needs a 4×4 or a bridge, get a quote. In our experience remote haulage can add $3k–$12k depending on access and distance.

Step 4: Add contingency — 12% is sensible for rural NSW, bump to 15% if there’s heritage or unknowns.

4. Real‑world examples and decisions

Example A: Barn near Dubbo, flat access. The owner chose insulated metal panels and saved $7k on labour and shortened build time by two weeks. Logistics cost was low.

Example B: Armidale property with narrow gravel track. Crew had to set up a temporary pad and generator; logistics jumped by $6k and the build stretched two weeks because of weather.

These choices directly move the barn conversion cost number. Pick the solution that fits your farming calendar, not just the lowest quote.

5. Quick decision table to help you choose

| Item | Option | Notes / Decision Tip |

|---|---|---|

| Foundation | Repair existing vs new slab | Repair saves up to 30% but check settlement; new slab adds longevity |

| Roof | Insulated metal panel vs tile | Metal panels quicker, cheaper to install, better for insulation on rural builds |

| Structural frame | Reinforce vs replace | Reinforce if sound, replace if termite/rot present — replacement raises cost fast |

| Insulation | Batts vs spray foam | Spray foam costs more up front but reduces condensation risks in cold valleys |

| Logistics | Standard delivery vs 4×4 delivery | Plan for remote access; factor $2k–$10k depending on distance and obstacles |

6. Final allocation and tracking

Make a rolling 12‑week cash flow. List supplier invoices, deposit dates, staged payments and hold one control column for change orders.

Tip: freeze non‑essential finishes until structural and services are signed off. You’ll usually find easy savings there without risking the build.

If you want a rigorous estimating method, industry cost guides can help with unit rates and contingencies — they’re worth a look when you’re comparing quotes (HVS cost estimating guidance).

In our experience, owners who do this work up front save the most time and money. You’ll know where each dollar is going, you’ll sleep better, and your barn conversion cost becomes a plan you can actually deliver.

Step 5: Managing Construction Timeline and Unexpected Issues

Picture this: the first beams are up, the crew’s humming, and you’re already checking the calendar for the next big weather window. That moment of relief can turn into a sprint if the timeline slips, and suddenly the barn conversion cost balloons.

Why a realistic schedule matters

In our experience across Tamworth, Armidale and the far‑west, the biggest surprise isn’t the material price – it’s the hidden days you didn’t plan for. A two‑week delay because a 4×4 couldn’t reach the site adds fuel, overtime and, yep, extra dollars to the bottom line.

So, what should you do now?

Step‑by‑step timeline toolbox

1. Map out every critical path activity. Grab a whiteboard or a simple spreadsheet and list the big milestones – demolition, foundation, framing, roof, services, finishes. Under each, note the dependencies. For example, you can’t order insulated metal panels until the roof deck is inspected.

2. Add a weather buffer. Rural NSW can swing from a scorching summer to a sudden cold front. Build in a 5‑7 day cushion around any outdoor work. It looks like “extra days” on paper, but it protects you from rain‑related hold‑ups that would otherwise cost $1‑$2k per day in crew standby.

3. Factor 4×4 logistics early. If the site requires a 4×4 delivery, get a quote from the start and lock in a date. Our crew usually schedules the heavy‑load day first thing in the week, so a missed slot doesn’t push the whole schedule back.

4. Set weekly checkpoints. Every Friday, walk the site with the foreman and compare actual progress to the plan. Note any slippages, then decide – do we compress the next task, bring in extra hands, or accept the delay and adjust the cash flow?

5. Keep a live cash‑flow tracker. Link each schedule change to a cost impact. If a storm forces a pause, record the extra $ for site protection, equipment rental, and any additional insurance premium. Seeing the numbers in real time keeps the barn conversion cost transparent.

Common unexpected issues (and how to tame them)

- Soil surprises. A hidden water table can turn a slab pour into a mini‑excavation. Mitigate by doing a pre‑construction soil test – a $300 investment that saves thousands later.

- Material hold‑ups. Lead times for spray‑foam insulation can stretch to six weeks. Order as soon as the foundation is poured and keep a backup batts stock on site.

- Heritage hiccups. If a heritage clause surfaces mid‑build, you might need to redo a cladding detail. Keep a contingency of 10‑12% earmarked for compliance changes.

- Livestock interference. Sheep or cattle wandering onto the site can halt work. Set up temporary fencing and schedule deliveries when the herd is penned elsewhere.

Each of these hiccups has a cost fingerprint. By logging them as they happen, you prevent the “unknown” from creeping into the final barn conversion cost.

Quick checklist to stay on track

- Confirm 4×4 access route and secure a delivery window.

- Lock in weather‑proof storage for materials.

- Run a soil moisture test before the slab.

- Schedule weekly progress meetings with a clear “what’s delayed” agenda.

- Update the cash‑flow sheet every time a schedule shift occurs.

Remember, a timeline isn’t set‑in‑stone; it’s a living document. Treat it like a farm’s grazing plan – you adjust when the rain comes early or the herd moves.

When you keep the schedule tight and the unexpected issues logged, the barn conversion cost stays where you expect it – not spiralling into an unbudgeted nightmare. And that peace of mind? It’s worth every extra minute you spend planning.

Step 6: Final Touches – Kitchen and Bathroom Renovations for Country Homes

Alright, the structure’s up, the roof’s on, and you can already picture the mornings with coffee by the new windows. Now it’s time to bring the heart of the home to life – the kitchen and bathroom. Those spaces are where daily comfort meets resale value, so getting them right can actually pull the barn conversion cost in a favourable direction.

Start with a realistic budget snapshot

Before you pick tiles or tap into the pantry, sit down with your spreadsheet and allocate a percentage of the overall barn conversion cost to the wet rooms. We usually see 15‑20% of the total budget go on kitchen and bathroom finishes. If you’re on a tight line‑item, note where you can trim – maybe a prefabricated cabinet block instead of bespoke joinery.

Design for the farm lifestyle

Think about the everyday. A cattle station owner needs a laundry that can handle muddy work boots, while a retiree in Armidale might prioritise a low‑step shower with grab rails. Choose durable, low‑maintenance finishes: ceramic or porcelain tiles that resist salt‑crust, stainless‑steel sinks that won’t corrode, and solid‑core doors that stand up to humidity.

And remember, a country kitchen isn’t just about looks; it’s a workspace. A work‑triangle layout – fridge, stove, sink – keeps traffic flowing. In our experience, a compact island with built‑in drawers adds storage without inflating the footprint.

Plumbing and drainage – the hidden cost driver

Most surprises in a barn conversion pop up in the wet zone. Old timber walls can hide damp, and a mis‑routed waste pipe can cost a few thousand to fix later. Start by mapping the existing service lines and then plan new runs that stay clear of structural beams.

Running a dedicated rainwater tank for garden irrigation can also shave water bills and boost sustainability credentials – a nice selling point if you ever list the property.

Lighting that works after sunset

Rural evenings stretch long, so layered lighting is a must. Overhead LED downlights give bright, even illumination for cooking, while under‑cabinet strips add task light without harsh glare. In the bathroom, a dimmable vanity light helps you shave a beard or apply makeup without blinding glare.

Don’t forget outdoor safety: motion‑sensor lights along the back‑door path keep the driveway clear after a night shift.

Finishing touches that add personality

A splash of colour on the kitchen splashback – think muted ochre or sage green – ties the space to the surrounding bushland. Open‑shelf shelving lets you display a prized copper pot or a set of mason jars, giving the room a lived‑in feel.

For the bathroom, a reclaimed timber vanity top adds warmth, and a simple timber‑frame mirror echoes the barn’s original beams. Little details like brushed‑nickel taps or a vintage‑style claw‑foot tub can make the space feel curated, not cookie‑cutter.

Choosing fixtures that fit your budget

When you’re eyeing a new gas cooktop or a high‑efficiency dual‑flush toilet, compare the upfront price with the long‑term operating cost. A low‑flow faucet might cost $30 more than a standard one, but it can shave $150‑$200 off your water bill each year – a win for your pocket and the environment.

Local suppliers in Tamworth or Dubbo often stock farm‑friendly ranges that are built to withstand dust and temperature swings. Ask for a sample finish before you commit; a quick test in the sun will reveal if the colour will fade under the NSW glare.

Sustainability touches that pay off

Installing a heat‑recovery ventilation unit in the kitchen can reclaim warm air and cut heating bills by up to 15%. In the bathroom, a solar‑heated water system paired with an insulated tank reduces reliance on the grid, especially useful when you’re off‑grid on a cattle station.

Even simple things – like using recycled glass tiles or reclaimed timber for a vanity – add story value that resonates with future buyers who appreciate eco‑friendly upgrades.

Final inspection and handover

Once the finishes are set, walk the space with your builder and a checklist. Verify that all taps have a steady flow, that cabinet doors close flush, and that the exhaust fan runs quietly. In our experience, a quick 30‑minute “wet‑room walk‑through” before the final sign‑off catches the last drip or squeak that could otherwise become a costly call‑out later.

If everything checks out, ask for a maintenance guide that lists cleaning schedules for tile grout, sealants for timber, and the recommended service interval for any mechanical appliances. That little document keeps the new kitchen and bathroom humming for years and protects the barn conversion cost you’ve just invested in.

Step‑by‑step checklist

- Confirm the budget slice for kitchen & bathroom (15‑20% of barn conversion cost).

- Choose durable finishes: porcelain tile, stainless steel, solid‑core doors.

- Map existing plumbing; plan new lines away from structural elements.

- Lay out the work triangle; consider a compact island for storage.

- Specify LED lighting layers – ceiling, task, and safety.

- Select one or two statement pieces (splashback colour, reclaimed vanity).

- Get three quotes from local trades; factor 4×4 delivery if needed.

- Add a 5‑10% contingency for unexpected wet‑room issues.

Once the finishes are locked in, our crew at Awesim Building Contractors can coordinate the final install while keeping the 4×4 logistics in mind – we’ve hauled cabinets up gravel tracks in Bourke without a hitch. The result? A kitchen that feels like the centre of a country home and a bathroom that’s as functional as a farm shed but far more comfortable.

Take a moment now to walk through your future kitchen in your head. Picture the smell of fresh coffee, the clink of mugs, and the easy flow of daily chores. If that vision feels right, start ticking the checklist above – the sooner you lock down those details, the smoother the last stretch of your barn conversion will be.

FAQ

What is the typical barn conversion cost in NSW?

In most regional NSW projects the total barn conversion cost lands somewhere between $120,000 and $250,000, depending on size, condition and how remote the site is. A modest 120‑sqm conversion with basic finishes might sit near the lower end, while a larger, heritage‑sensitive build with premium cladding can push the figure toward the high‑end. Always build a 10‑15% contingency for unexpected site‑specific items.

How do I factor 4×4 logistics into my budget?

Remote farms often need a 4×4 vehicle to haul materials up gravel tracks. The extra cost isn’t just fuel – it includes hiring a specialised rig, possible bridge permits and extra labour for loading. In our experience a typical 4×4 delivery adds $2,000‑$8,000 to the barn conversion cost, so list it as a separate line‑item early on. That way you won’t be surprised when the truck finally shows up.

What are the biggest hidden costs that can blow my budget?

Hidden costs usually hide in three places: soil surprises, heritage requirements and utility upgrades. A water‑table issue can mean extra excavation, costing a few thousand dollars. If your barn sits on a heritage‑listed site, you may need an impact statement and specialised architect fees. Finally, extending power or water to a remote location often adds $1,500‑$4,000. Spot these early with a site‑assessment and you can plan them into the barn conversion cost.

Should I hire a licensed certifier or try to DIY the paperwork?

Going DIY might save a little on certifier fees, but the risk of a rejected Development Application (DA) usually outweighs the saving. A licensed certifier knows the Building Code of Australia, council quirks and how to fast‑track approvals. In our experience a professional certifier can shave weeks off the schedule, which in turn protects your budget by avoiding delays and stop‑work orders.

How much should I allocate for kitchen and bathroom finishes?

Most owners earmark about 15‑20% of the overall barn conversion cost for wet‑room finishes. That covers durable tiles, stainless‑steel fixtures, solid‑core doors and a modest island or vanity. If you’re on a tighter budget, consider prefabricated cabinet blocks and bulk‑ordered LED lighting – you’ll still get a functional space without inflating the total cost.

Can I reduce the cost by reusing existing structural elements?

Absolutely. If the original timber frame or roof trusses are still sound, reusing them can cut structural spend by 10‑15%. The key is a thorough inspection – look for rot, insect damage or warping. When we’ve salvaged good‑condition beams on a Dubbo property, the saved money was redirected into higher‑grade insulation, which lowered long‑term heating bills.

What’s the best way to keep the project on schedule and within budget?

Treat the timeline like a living spreadsheet. Map out every critical path activity, add a 5‑7 day weather buffer and lock in delivery dates for big items (like insulated metal panels) before the build starts. Hold weekly walk‑throughs with your foreman, record any delays and immediately tie them to a cost impact. That real‑time tracking keeps the barn conversion cost transparent and helps you make quick decisions before small hiccups become big overruns.

Conclusion

We’ve walked through the whole barn conversion cost journey – from budgeting the basics, wrestling with permits, picking materials, tracking the timeline, right through to the final kitchen and bathroom touches.

So, what does it all mean for you? It means you now have a clear roadmap that keeps surprises out of the bottom line and helps you make confident decisions at every stage.

Remember, the biggest budget levers are reuse of sound timber, smart logistics (especially that 4×4 delivery), and a solid contingency that reflects the remote NSW realities.

In our experience, a simple spreadsheet that ties each line‑item to a cost impact – and a weekly walk‑through with the foreman – can shave thousands off a project that might otherwise balloon.

Don’t forget the “human” side: schedule work around harvest or calving seasons, involve your family in the vision, and keep an eye on those weather buffers. Those tiny details protect both your peace of mind and your wallet.

Ready to turn the plan into a finished country home? Give Awesim Building Contractors a call, and we’ll help you lock in the numbers, lock down the logistics, and lock the doors on a stress‑free build.

And when you see the sun spill over the new windows, you’ll know every dollar was worth it.