A well-built shed is the backbone of any NSW farm, acting as the hub for your machinery, livestock, and supplies. But where do you even start? This guide is designed to cut through the noise, helping you figure out what a ‘small farm shed’ really means for your property and tackling your biggest worries—durability, function, and the unique challenges of rural construction.

Building Your Essential Small Farm Sheds in NSW

On any rural property, a shed is far more than just four walls and a roof; it’s a direct investment in your farm’s efficiency and organisation. Think of it as the central nervous system of your operation—the place where tools are kept safe, equipment is properly maintained, and your valuable assets are shielded from the harsh Australian elements. For many farmers, a small farm shed hits that perfect sweet spot, giving you all the utility you need without the overwhelming cost and footprint of a huge industrial building.

But let’s be honest, building anything in a rural area comes with its own set of headaches. One of the biggest hurdles we see property owners facing across New South Wales is simple logistics. Just getting labour, materials, and heavy machinery to a site that might be hours from the nearest town can quickly turn into a costly and complicated mess.

Overcoming Rural Construction Challenges

This is where smart planning and partnering with the right team really makes a world of difference. Traditional construction methods often hit a wall when faced with unsealed roads, steep terrain, or properties that are well and truly off the beaten path. These logistical nightmares can lead to frustrating delays, bloated costs, and corners being cut on the final build.

We actually built our entire business to solve this exact problem. After seeing the constant struggles rural landowners faced, we invested in a specialised fleet of heavy 4×4 trucks. This unique capability is at the very core of what we do.

Our heavy 4×4 trucks are purpose-built to get into the most remote properties across New South Wales. It means we can bring all the necessary crew, labour, and materials right to your site, when and where they’re needed the most. This keeps your project running on schedule and on budget, no matter how isolated your location is.

Before we even think about putting up the first steel frame, we need to map out a solid plan. Kicking things off with the right preparation is essential, especially when it comes to the foundation—the literal base for your shed’s success.

Key Considerations For Your Small Farm Shed Project

Getting your project right from the start means asking the right questions. This table breaks down the most important factors to think about before you even break ground.

| Consideration | Key Questions to Ask | Why It Matters |

|---|---|---|

| Site Preparation | Is the ground level? Does water drain away from the site properly? Is the area clear of trees and obstacles? | Proper drainage and a level pad prevent water damage, shifting, and structural stress down the line. |

| Soil Type | What kind of soil do you have (clay, sand, rock)? Will it support the weight of the shed and its contents? | The soil dictates the best foundation type—whether it’s a slab, piers, or footings—to ensure long-term stability. |

| Intended Use | Will you be storing heavy tractors and machinery? Is it for hay and feed? Or will it shelter small livestock? | The shed’s purpose determines the required strength of the foundation. A machinery shed needs far more support than a simple storage shed. |

| Access & Logistics | How will trucks and equipment get to the site? Are there gates, fences, or natural barriers to consider? | Planning for access avoids costly delays and ensures materials and crews can get in and out efficiently. |

Taking the time to work through these points will save you a world of trouble and ensure the final structure is perfectly suited to your needs.

A Foundation for Success

The project really begins long before the first steel frame is bolted together. It all starts with a solid plan and an even more solid foundation. The right base doesn’t just hold the structure up; it protects it from shifting soil and moisture, guaranteeing it will last for decades.

A professionally poured and cured foundation is simply non-negotiable for a durable shed. To get a better handle on why this step is so vital, you can learn more about the specifics of expertly constructed concrete slabs in our detailed guide. This initial investment in quality groundwork is what ensures your shed will stand strong against the tests of time and tough farm use, making it a reliable asset for years to come.

Designing a Shed That Truly Works For You

Designing your small farm shed is a bit like planning a new kitchen or workshop. Every single element needs a clear purpose and a designated spot. While a generic, off-the-shelf layout might seem like the easy option, it rarely delivers the practical efficiency a working farm demands. The real value is in a design that’s tailored to your specific day-to-day operations.

This means thinking beyond just four walls and a roof. You need to consider exactly how you’ll use the space. Is it going to be a dedicated machinery bay, a safe shelter for livestock, or a functional workshop for repairs and projects? A thoughtfully customised layout makes sure every square metre is working hard for you, boosting productivity and making daily tasks that little bit easier.

And remember, even the most brilliant design is useless if you can’t actually build it on your property. Logistics are everything for those hard-to-reach farms. That’s why we have access to heavy 4×4 trucks to access the most remote properties around New South Wales. This allows us to bring in all the labour and materials right where and when they’re needed the most, turning your custom design into a reality, no matter how far off the beaten track you are.

Planning for Machinery and Vehicle Storage

One of the most common jobs for a small farm shed is protecting expensive machinery and vehicles. Getting your tractor, ute, quad bike, and other implements out of the harsh NSW sun and rain is critical for extending their lifespan and holding their value. The secret to a great machinery shed is getting the bay sizes and access points right from the start.

A standard ute will fit comfortably in a bay that’s around 3 metres wide. But for a tractor with attachments, you’ll want to look at something closer to 4.5 to 6 metres to give you plenty of room to get in and out without a fuss. Height is just as important—a clearance of at least 3.5 metres is a good starting point, but you’ll need to measure your tallest piece of equipment to be absolutely sure.

Consider a layout that gives you the best of both worlds: one or two fully enclosed bays for secure, weatherproof storage, and one or two open-front bays. The open bays are perfect for gear you use daily, offering grab-and-go access without messing around with doors. This hybrid approach delivers the perfect balance of security and convenience.

Creating Safe and Efficient Livestock Shelters

If you’re planning a shed for livestock, the design priorities shift towards animal welfare, safety, and ease of management. For sheep, goats, or calves, the main goal is to create a space that is dry, well-ventilated, and free from drafts.

A well-designed livestock shelter isn’t just about protection from the elements; it’s about creating a low-stress environment that promotes animal health and simplifies your daily chores. Smart design choices directly contribute to a healthier, more productive flock or herd.

Good ventilation is non-negotiable. Poor airflow can lead to respiratory issues caused by ammonia buildup from animal waste. Things like strategically placed windows, ridge vents, or whirlybirds create natural airflow that keeps the air fresh and reduces moisture. Don’t forget the flooring, either. A concrete floor is a breeze to clean and disinfect, while a deep litter system over a dirt or gravel base can provide warmth and comfort.

The Great Door Debate: Roller vs Sliding

The type of doors you choose will have a huge impact on your shed’s day-to-day usability. The two most popular choices, roller doors and sliding doors, each have their own pros and cons depending on what you need.

- Roller Doors: These are fantastic for security and creating a good weather seal. They roll up neatly out of the way, so they don’t need any extra space to operate, making them ideal for tighter areas. The only catch is they are generally limited in width, usually maxing out at around 5 metres.

- Sliding Doors: If you need extra-wide openings for large machinery like combine harvesters or air seeders, sliding doors are the clear winner. They can be built to cover massive spans, but they do require clear wall space to slide open.

Ultimately, the best choice comes down to what you’re using the bay for. Roller doors are brilliant for standard vehicle bays and secure workshops, while sliding doors are the go-to solution for oversized machinery access.

Choosing Materials Built for the Australian Climate

The real value of your small farm shed comes down to its bones—the materials you choose and the foundation it sits on. A shed isn’t just a kit you assemble; it’s a complete system where every single part has to hold up against the relentless NSW climate. We’re talking scorching summer sun, torrential rain, and everything in between.

Getting this right from the start is the best way to protect your investment for years to come. It means looking past the paint colour and focusing on what really matters. Will the frame stand up to termites and bushfires? Is the foundation suited to your specific soil type? These are the questions that decide whether you get a lasting asset or a maintenance nightmare.

Of course, even the best materials are useless if you can’t get them to your property. That’s why we have access to heavy 4×4 trucks to access the most remote properties around New South Wales. It means we can get the labour and quality components on-site, where and when they are needed the most, no matter how far off the beaten track you are.

Steel vs. Timber: The Great Framing Debate

When it comes to your shed’s frame, the choice in Australia really boils down to steel or timber. While timber has that classic, traditional feel, Australian-made steel has become the undisputed champion for rural construction, and for good reason.

Think of a steel frame as the ultimate defence against a farm shed’s natural enemies. It’s non-combustible, which is a massive advantage in any bushfire-prone area. It’s also 100% termite-proof, which means you can forget about the constant chemical treatments timber needs. On top of that, high-tensile steel frames are engineered to be incredibly strong but lightweight, giving you straight, true walls that won’t warp or twist over the decades.

Timber, on the other hand, is vulnerable. It needs chemical treatments to fight off pests and rot, and even then, moisture can cause it to warp and weaken. For a low-maintenance structure built to last, steel is almost always the smarter choice.

Choosing the Right Foundation for Your Land

The foundation is what anchors your shed to the ground, and it’s definitely not a one-size-fits-all deal. The right choice depends entirely on your property’s conditions—the slope, the soil type, and what you plan to use the shed for. Get this wrong, and you’re setting yourself up for serious structural problems later on.

Here’s a simple rundown of the most common options:

- Concrete Slab: This is a solid, reinforced concrete base poured over the shed’s entire footprint. It gives you an exceptionally strong, level, and easy-to-clean floor, making it ideal for workshops or machinery storage. Slabs work best on relatively flat ground.

- Concrete Piers: If your land is sloped or uneven, piers are the perfect solution. These are individual concrete columns dug deep into the ground at key points. The shed frame then bolts onto the piers, lifting the whole structure clear of the uneven terrain.

- Footings: These are concrete strips poured into trenches around the shed’s perimeter. They provide a solid base for the walls and are often paired with a gravel or dirt floor inside—a practical option for livestock shelters.

Your shed is only as strong as its connection to the ground. Investing in the correct foundation for your specific site conditions is the single most important decision you can make for its long-term stability and security.

A small farm shed can play countless roles, and this often leads to a wide range of DIY solutions, especially for livestock. A basic chicken shelter might be built for as little as AUD $150 using leftover timber and tin, while a more serious cow shed with steel posts and concrete footings could easily exceed AUD $4,000. It just goes to show the practical, budget-conscious mindset of many farmers, though it’s always critical to balance savings with structural safety and animal welfare.

Choosing the right materials isn’t just about strength; it’s also about building responsibly. To learn more about this, check out our insights on the complete guide to sustainable farm building materials. Making smart choices now ensures your shed is not only tough but also thoughtfully built.

Understanding the Real Costs of Your Farm Shed

Budgeting for a new small farm shed isn’t just about the attractive price tag on a kit. That figure is only the starting line. The final number on your invoice is a sum of many parts, and getting a clear picture of all of them is the key to creating a realistic financial plan without any nasty surprises down the track.

To get to the finish line, you need to account for several critical, often-overlooked expenses. These can include everything from initial site preparation and earthworks to the cost of pouring a solid concrete foundation. On top of that, there are council application fees, the cost of specialised labour, and charges for connecting services like water or power.

Breaking Down the Budget Components

It helps to think of your shed budget in three main chunks: the structure itself, the site work, and the finishing touches.

The structure is the steel frame, roofing, and wall cladding. Here, your choices in materials, like steel thickness or Colorbond options, will directly influence the cost. Site work covers everything needed to get your land ready—and depending on your property’s terrain, this can be a pretty significant expense.

Finally, the finishing touches are all the custom features that make the shed truly yours. This is where you’ll budget for extras like insulation, internal walls for a workshop, roller doors, windows, or even plumbing. It’s vital to sort out your “must-haves” from your “nice-to-haves” at this stage. For more tips on getting your numbers right, check out our guide on budgeting secrets for successful construction farm projects.

The Impact of Land Value on Shed Costs

The rising value of farmland also plays a subtle but important role in the economics of building new infrastructure. As land becomes more valuable, the pressure to maximise its productivity increases. This makes quality infrastructure like a small farm shed a necessary investment, even if it feels like a significant one.

This economic reality is backed up by recent research. Australian broadacre farmland prices have surged, increasing more than eightfold since 1992. While this has been a boon for established landowners, it also drives up the associated costs of production, including building new sheds and yards. It creates a challenging cycle where higher land values escalate the costs of essential buildings, which can impact a farm’s overall profitability. You can read the full research on how lofty farmland values could be hurting some farmers to get a deeper understanding of this trend.

Controlling Costs with Smart Logistics

One of the biggest variables in any rural construction budget is logistics. Simply getting materials and skilled labour to a remote property can be incredibly expensive and can easily derail an otherwise well-planned project. This is a challenge we’ve specifically built our business to solve.

We have access to heavy 4×4 trucks to access the most remote properties around New South Wales. This capability allows us to bring in labour and materials where and when they’re needed the most, controlling logistical costs that can cripple other projects and keeping your budget on track.

This logistical control is a key part of our service. By eliminating the uncertainty of remote access, we provide cost certainty right from the start. Our goal is to demystify all the numbers involved, giving you a clear and transparent path to confidently investing in a high-quality small farm shed that will serve your needs for decades to come.

Navigating Council Approvals and Building Codes

Let’s be honest, dealing with council regulations can feel like the most painful part of getting a new farm shed built. But it doesn’t have to be a nightmare. These rules are there for good reason: to make sure your new shed is safe, compliant, and built to stand up to whatever the Aussie climate throws at it. For any rural property in NSW, getting this right is non-negotiable.

Skipping this step is a recipe for disaster. You could be hit with massive fines, an order to tear down your brand-new shed, or find yourself in a serious bind with your insurer if something goes wrong down the track.

Understanding the Approval Pathways

In New South Wales, there are generally three ways your shed project can go, depending on its size, location, and what you plan to use it for. It’s crucial to figure out which path you need to take before a single shovel hits the dirt.

- Exempt Development: Some tiny, low-impact sheds might not need any formal approval at all. But the rules are incredibly strict, and almost any shed that’s actually useful on a farm will be too big to qualify.

- Complying Development Certificate (CDC): This is the fast-track option. It’s a streamlined approval for straightforward builds that tick all the boxes of a state-wide standard. If your shed design meets these specific criteria, a private certifier can issue a CDC without the full council assessment process.

- Development Application (DA): This is the most common route for most small farm sheds. A DA is a formal application that your local council assesses against its own specific planning rules and policies.

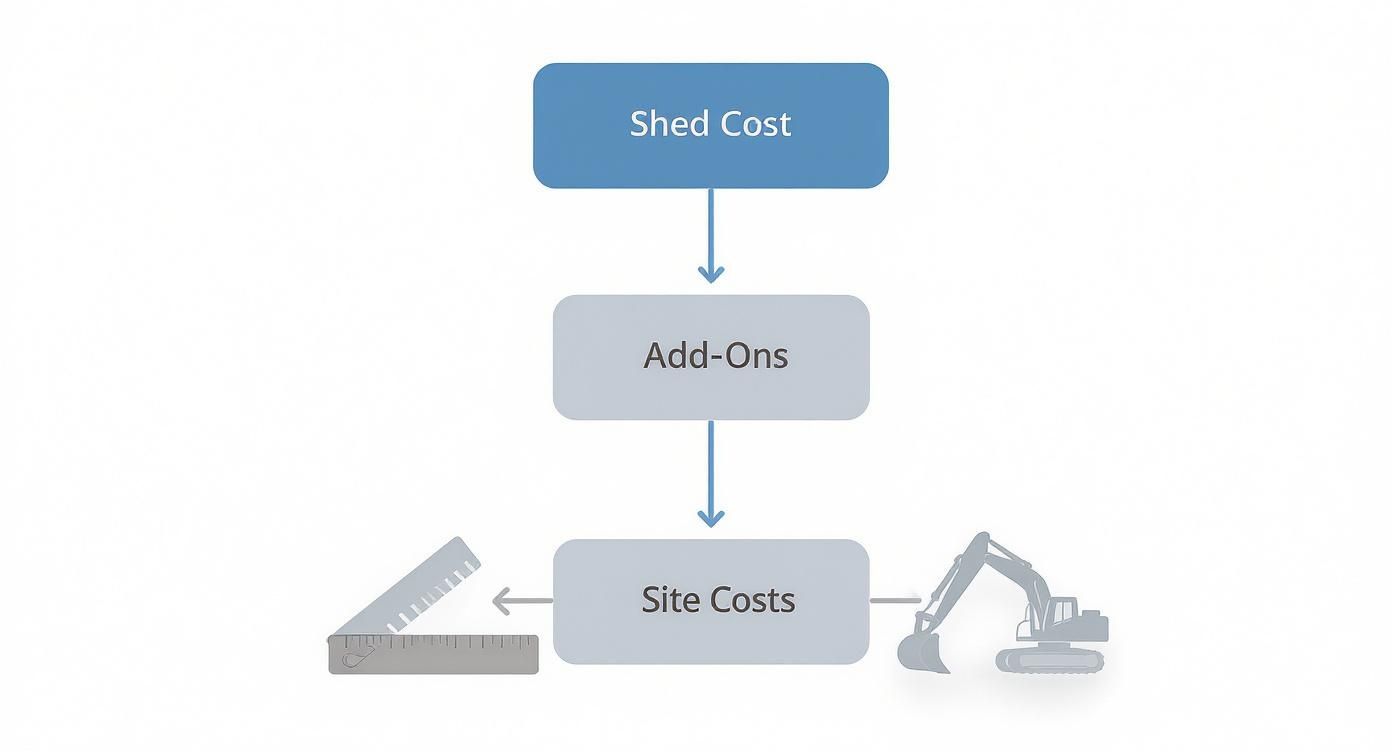

This decision tree gives you a good visual on the key things that influence your shed’s final price, which often ties directly into how complex your council approval process will be.

As the infographic shows, the base price is just the starting point. Add-ons, site preparation, and foundation choices can all have a big impact on the total investment and the level of approval you’ll need.

The Importance of Australian Standards

On top of council approval, every single shed built in Australia must comply with the National Construction Code (NCC) and the relevant Australian Standards. Think of these as the official rulebooks for the entire building industry. They dictate everything from the thickness of the steel to the engineering required for wind loads in your specific part of the country.

Sticking to the NCC and Australian Standards isn’t just about ticking boxes on a form. It’s a fundamental commitment to quality and safety, ensuring your shed is properly engineered for your property. It’s peace of mind that your gear, your livestock, and your family are protected.

This is exactly why we insist on using high-quality, Australian-made materials. They’re manufactured and tested to meet these precise standards, guaranteeing the structural integrity of your build from the ground up.

How We Manage the Entire Process For You

This is where we come in. Navigating the maze of paperwork, codes, and council red tape is what we do best, and our experience with local councils all across NSW makes a real difference. We handle the entire approval process for you, from start to finish.

We take care of preparing and lodging all the necessary documents, whether it’s for a straightforward CDC or a full DA. Our team makes sure your shed design is 100% compliant with all the relevant codes, which helps you avoid frustrating delays and rejections. It’s all about delivering a smooth, compliant, and completely stress-free build.

Even if your property is out in the sticks, our process doesn’t change. We have access to heavy 4×4 trucks to access the most remote properties around New South Wales. This means we can get the labour and materials to your site, where and when it’s needed the most, ensuring every project gets the same professionally managed construction process.

Right, you’ve got a handle on what it takes to plan, design, and budget for the perfect small farm shed. The final piece of the puzzle is picking the right partner to bring that vision to life. This is where Awesim is different—we’re not just builders, we’re specialists in solving the unique headaches that come with rural construction.

Our biggest advantage? Our specialised fleet. We have access to heavy 4×4 trucks to access the most remote properties around New South Wales. Where others see steep tracks and isolated sites as a logistical nightmare, we just see another day at the office. This unique capability means we get all the labour and materials to your site, exactly when and where they’re needed the most, keeping your project on track and on budget.

Your End-to-End Rural Building Partner

We offer a genuine end-to-end service designed to give you complete peace of mind. Our team manages every single stage, so you can get back to what matters—running your farm.

Our comprehensive service includes:

- Custom Design: We’ll sit down with you to map out a small farm shed layout that fits your operation like a glove.

- Council Approvals: Our team handles all the red tape, navigating the DA or CDC process with local councils across NSW to make sure everything is fully compliant.

- Flawless Construction: Our experienced builders use high-quality, Australian-made materials to put up a shed that’s built to last.

- Insurance Repairs: We’re also experts in managing and carrying out insurance repair work after storm, fire, or flood damage.

Choosing the right partner means finding a team that gets the realities of your property. We don’t just build sheds; we deliver practical solutions for the challenges of rural life, no matter how far off the beaten track you are.

Built for the Modern Australian Farm

The agricultural industry is always evolving. A recent snapshot of Australian agriculture shows that while some farm types have declined due to amalgamations, specialist operations like beef farms are on the rise. This shift is driving demand for more specific and robust infrastructure—think well-designed beef cattle sheds and other small farm sheds built for better animal welfare and efficiency.

We stay on top of these trends because we’re committed to building sheds that meet the real demands of modern farming. Let us handle the complexity of your next project.

Your Questions Answered

Here are some quick answers to the questions we get asked most often about building small farm sheds in NSW. These insights should clear up a few things and help you finalise your plans.

Do I Need Council Approval For a Small Farm Shed in NSW?

The short answer is: most likely, yes. While some tiny, low-impact structures might get away with being an ‘exempt development’, almost every functional farm shed needs some kind of formal approval. This is usually a Complying Development Certificate (CDC) or a full Development Application (DA).

What determines the path you’ll need to take? It comes down to your property’s zoning, the shed’s size and height, and its Bushfire Attack Level (BAL) rating. To be safe, it’s always best to assume you’ll need approval. We manage this entire process for our clients to make sure everything is above board and fully compliant with local council rules.

What Is the Typical Cost Per Square Metre For a Shed?

Giving a simple square-metre rate can be really misleading. The final cost of a shed depends on so much more than just its footprint, with the total investment covering a whole range of variables unique to your project.

These costs include things like the initial site prep, the type of foundation you need (a concrete slab costs more than piers), your choice of materials, how many doors and windows you want, and all the labour involved.

Site accessibility is another huge factor that can shift the final budget. We provide fully itemised quotes that break down every single cost, so you get a completely transparent and accurate budget with no hidden surprises.

How Long Does It Take to Build a Small Farm Sheds?

The whole process can be broken down into three stages: design, approvals, and construction. The initial design work can often be knocked over in a couple of weeks.

The council approval stage is the real wild card. It can range from six weeks for a straightforward CDC to several months for a more complex DA. Once we have the green light and all the materials are on-site, the physical build of a typical small farm shed is usually finished in just 1-3 weeks. We coordinate every step to keep the project moving as smoothly as possible.

My Property Is Very Remote. Can You Still Build There?

Absolutely. In fact, that’s exactly what we specialise in. We’ve invested in a fleet of heavy 4×4 trucks purpose-built to get into remote and hard-to-reach terrain all across New South Wales.

This unique capability means we can bring all the necessary labour, materials, and equipment directly to your property. We’re set up to overcome the logistical headaches that stop other builders in their tracks, so we can handle the jobs in those out-of-the-way locations.

Ready to build a small farm shed that’s perfectly suited to your property, no matter how remote? The team at Awesim Building Contractors has the expertise and specialised equipment to manage your project from start to finish. Contact us today to discuss your vision.

2 Comments