Before you can even think about repairs, you have to get the diagnosis right. Figuring out if you’re looking at a few cosmetic scuffs or the first signs of a serious structural problem is absolutely the most important step in getting your timber floors back to their best.

Your Diagnostic Guide to Timber Floor Damage

Think of yourself as a floor detective. Timber floors have a way of telling you what’s wrong through what you can see, hear, and even feel underfoot. You just need to know how to interpret the clues. Here in New South Wales, the local environment—from the humid coast to the dry inland plains—heavily influences the kind of trouble you're likely to find.

This guide will walk you through identifying the common culprits, understanding what’s really causing them, and deciding what to do next. A proper assessment is non-negotiable, whether it's for a simple scratch or something far more sinister.

Common Signs of Surface and Cosmetic Damage

Most of the time, you'll be dealing with superficial damage from everyday life. It might seem minor, but letting it slide can open the door to bigger headaches later. Keep an eye out for these signs:

- Scratches and Gouges: These are the classic culprits, caused by everything from the dog’s claws and dragged furniture to grit on the bottom of your boots. Shallow scratches might just be in the finish, but a deep gouge can tear into the wood itself.

- Dullness and Fading: The protective topcoat on your floor will naturally wear down over time, especially in high-traffic zones like hallways. You’ll also see fading and discolouration in spots that get a lot of direct sun.

- Minor Stains: Small spills that are mopped up fast might leave a faint watermark, but they rarely affect the timber's structural integrity.

For these kinds of issues, a good sand and refinish is usually all it takes. This process strips back the damaged surface layer and seals the timber with a fresh, durable coat.

Identifying Deeper Structural Problems

This is where things get more serious. Structural problems compromise the stability and safety of your floor, and they almost always need a professional eye. Spotting them early can save you a fortune.

That persistent squeak might seem like a simple annoyance, but it could be a loose board or, worse, a problem with the subfloor joists. Gaps opening up between floorboards are another major red flag. A little bit of movement with the seasons is normal for timber, but if those gaps keep getting wider, you could have a humidity problem or an installation fault.

I can't stress this enough: always check for moisture. Water is timber’s worst enemy. It causes boards to cup (where the edges raise up) or crown (where the middle bulges), and if left unchecked, it will inevitably lead to rot.

Recognising Pest and Moisture-Related Threats

In NSW, the two biggest threats to any timber floor are moisture and termites. The damage starts small and hidden but can become catastrophic before you know it.

As you inspect your floors, you need to know what you're looking for. It pays to understand how to identify termites to catch an infestation before it destroys your home’s structure. Listen for hollow-sounding timber when you tap it, and look for tiny mud tunnels or unexplained piles of fine, sawdust-like frass.

Rot, on the other hand, is a fungal decay that thrives in damp wood. If an area feels spongy or soft when you walk on it, or if you can poke a screwdriver into it and it just crumbles, you’ve got rot. Those boards need to be cut out and replaced immediately to stop the fungus from spreading.

For complex jobs where you need to be certain, using modern tools can make a huge difference. Good inspection software, for instance, provides detailed checklists and reporting features to make sure nothing gets missed.

Practical DIY Fixes for Minor Floor Flaws

With the right approach and a bit of patience, many common timber floor problems are surprisingly manageable for a hands-on homeowner. Tackling these minor flaws yourself not only saves a bit of cash but also gives you a deeper connection to the character of your home. Think of this as your go-to guide for handling those smaller jobs with confidence.

We’ll focus on the usual suspects: those maddening squeaks, everyday scratches, and the odd loose board. While they might seem minor, they can really detract from the look and feel of your floors. For more ideas you can tackle yourself, these DIY floor repair tips offer some great additional guidance.

Silencing Pesky Squeaks

A squeaky floorboard is easily one of the most common complaints I hear about. That irritating noise is almost always caused by boards rubbing against each other or shifting against the subfloor. Before you think about pulling anything up, there are a few simple tricks to try.

One of the oldest and easiest solutions is to work some powdered graphite or even talcum powder into the seams around the noisy board. The powder acts as a dry lubricant, cutting down the friction that’s causing the racket. You’d be surprised how often this simple fix works.

If the powder trick doesn't cut it, you're likely dealing with a small gap between the floorboard and the joist underneath. If you’ve got access from a crawlspace, you can gently tap a thin, wedged shim into the gap. Just be careful not to hammer it in too hard—you could end up creating a noticeable bulge in the floor above.

Filling Scratches and Gaps

Scratches and small gaps are just a part of life with timber floors, but they're also quite straightforward to fix. The secret to a repair that doesn’t stick out like a sore thumb is choosing the right filler and getting the colour spot-on.

For those fine, surface-level scratches, you can often get away with using a wax repair stick or a stain-matching marker pen. These are designed to blend right in and hide minor imperfections with almost no effort.

Deeper gouges or gaps, however, call for a good-quality wood putty. For a professional-looking result, here’s what you do:

- Prep the Area: First, give the scratch or gap a thorough clean to get rid of any dust or debris.

- Apply the Putty: Using a small putty knife, press the filler firmly into the damaged spot. It's a good idea to overfill it slightly, as most putties shrink a little as they dry.

- Smooth and Wait: Scrape off the excess with your knife for a smooth finish, then let it dry completely based on the manufacturer’s directions.

- Final Sand: Once it has fully cured, give the filled area a light sand with fine-grit sandpaper until it’s perfectly level with the surrounding floor.

Here’s a pro tip I always share: test your putty or stain on a spare bit of timber or in a hidden spot first. This simple step guarantees you've got a perfect colour match before you apply it somewhere obvious.

Securing a Loose Floorboard

A single loose board doesn't always need replacing. Often, you can secure it quite easily. If you can get to the floor from below, the best method is to drive a couple of screws up through the subfloor and into the bottom of the loose board. Just make sure the screws are short enough that they don't pop through the top surface!

No access from underneath? No problem. You can face-nail the board from above. Drill small pilot holes first, then drive finishing nails through the board into the joist below. Use a nail punch to sink the heads just below the surface, and then hide the holes with a dab of matching wood putty. It’s a solid, lasting fix for an isolated problem board.

When It’s Time to Call in a Professional Floor Repair Expert

There’s a real satisfaction in fixing things around the house yourself. But when it comes to timber floors, knowing your limits is key. Some jobs look simple on the surface but can quickly spiral into a costly mess without the right expertise. Pushing ahead with a complex repair can do more harm than good, potentially damaging your floors beyond recovery.

Recognising when to put down the tools and pick up the phone protects your home's value and, more importantly, its structural integrity. Certain problems signal that you're dealing with something more than just a cosmetic issue, and that’s when a seasoned professional is your best bet.

Red Flags That Demand an Expert Eye

If you’ve spotted any of the following, it’s a clear sign that the problem runs deeper than a simple DIY fix can handle. These issues often have hidden causes that an expert is trained to find and resolve properly.

- Widespread Water Damage: A major leak or flood can leave boards cupped, warped, and blackened. This isn't just about replacing the visible damage. A professional needs to assess the subfloor, check moisture levels, and replace timber without trapping dampness that could cause future problems.

- Deep or Spreading Rot: If you can push a screwdriver into a soft, spongy board, you’ve got rot. This isn't something you can just patch up. Fungal decay needs to be completely cut out by an expert to stop it from spreading to healthy boards and, worse, your structural joists.

- Termite or Borer Damage: The trouble with timber pests is that they hollow out your floor from the inside. What looks fine on the surface can be dangerously weak underneath. A professional can gauge the true extent of the damage, replace the affected timber, and make sure the new boards blend in seamlessly.

- Major Structural and Subfloor Problems: Are your floors noticeably sagging or crowning? Do they feel bouncy or unstable when you walk on them? These are not floorboard issues; they’re subfloor issues. This points to problems with your stumps or joists and requires a proper structural assessment and specialised repair skills.

The real value of a professional is their ability to see what you can’t. They don't just fix the symptom; they diagnose the root cause—be it a hidden plumbing leak, poor underfloor ventilation, or a failing bearer—to ensure the repair is a permanent solution, not just a band-aid.

The Professional Advantage: Specialised Gear and Materials

It’s not just about skill and experience. A professional flooring specialist arrives with an arsenal of equipment that’s simply not practical for a homeowner to own. We’re talking about industrial-grade sanders with powerful dust extraction, digital moisture meters, and precision saws that deliver a flawless finish.

They also have access to a far wider range of timber species and trade-only finishes. Trying to match a 50-year-old floorboard from the local hardware shop is a recipe for a patchwork disaster. A specialist can source or machine timber for a perfect match, restoring your floor’s original, uniform look. Our team provides comprehensive flooring repairs that do exactly that.

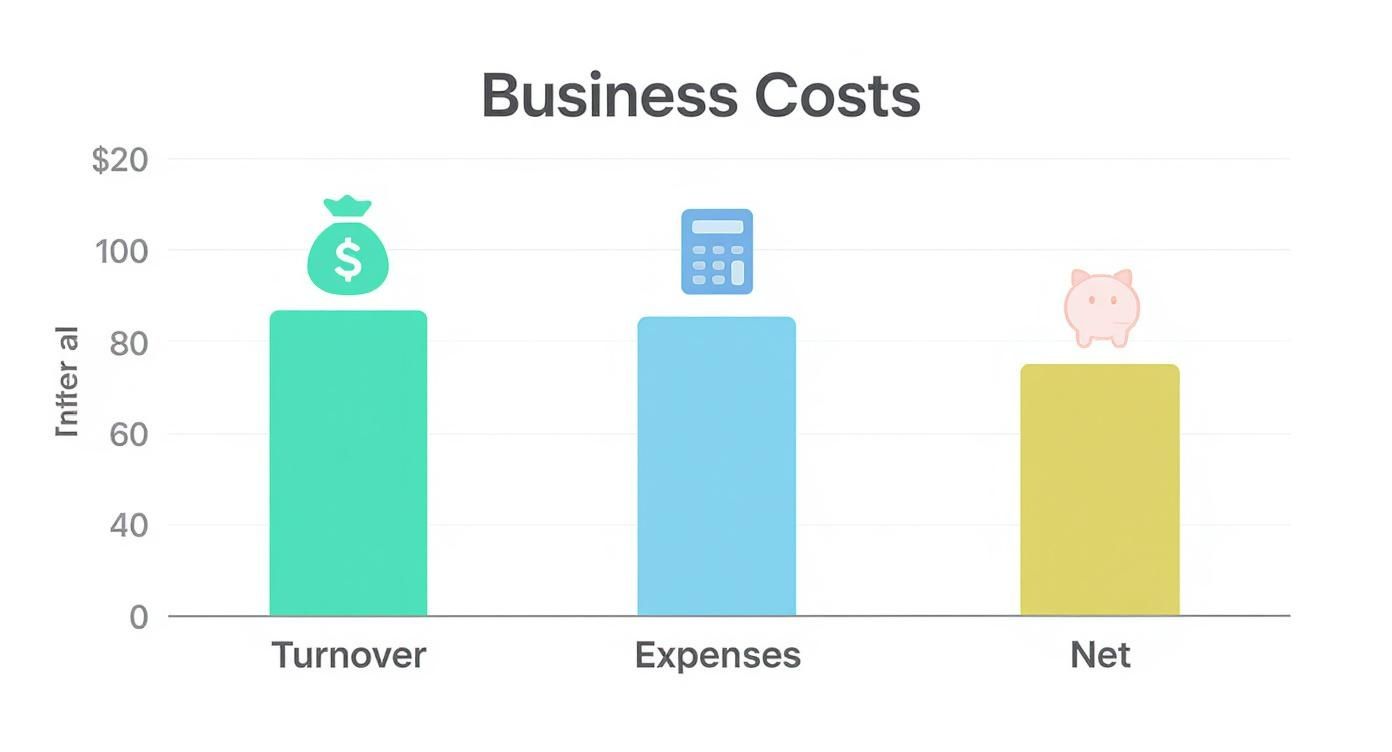

The costs in this industry reflect the investment required. For a typical timber floor sanding business in Australia, operational expenses like materials, high-end equipment, and labour can make up 50% to 71% of turnover. You can get a better sense of these industry benchmarks on the ATO website. That investment is what guarantees a result that will stand the test of time.

Overcoming Rural NSW Access Challenges

For those of us living out in regional and rural New South Wales, just getting tradespeople—let alone the right materials—to the property can be half the battle. This is where our setup truly makes a difference. We operate a 10-tonne 4×4 truck specifically to bring in labour, materials, and equipment for the most remote properties.

This heavy-duty vehicle is our mobile workshop, loaded with all the timber, tools, and supplies needed for the job. It allows us to bring a full crew and everything they need directly to you, no matter how far off the beaten track you are.

Whether your property is at the end of a winding dirt road or involves a few creek crossings, we have the capability to get there and get the job done. This self-sufficiency means we can tackle major timber floor repairs without the logistical headaches and delays that often plague projects in the country, ensuring your home gets the same level of craftsmanship you’d expect in the city.

Understanding the Real Cost of Timber Floor Repairs

Trying to budget for a timber floor repair can feel a bit like guesswork. Is it a few hundred dollars or a few thousand? The final quote you receive isn't just a number plucked from thin air; it’s a detailed calculation based on what’s actually happening with your floor.

From the species of timber under your feet to the exact nature of the damage, several key things determine the cost. Let's break down what really goes into the price, so you can plan your budget with a bit more confidence.

What Drives the Final Quote?

The price of any professional repair job is a sum of its parts. For timber floors, the biggest variables are always the type of wood we're working with, how bad the damage is, and the specific techniques needed to get the job done right.

Fixing a few minor scratches on a common pine floor, for instance, is a world away from replacing several boards of a premium hardwood like Jarrah that have been destroyed by termites. Likewise, a straightforward sand and refinish is a much smaller job than tackling structural rot that extends into the subfloor.

- Type of Timber: Locally sourced woods like Tasmanian Oak are generally more affordable than premium or rare species like Blackbutt or Ironbark, which naturally have a higher material cost.

- Extent of Damage: Are we dealing with surface-level cosmetic issues, or is there deeper, structural damage from moisture or pests? The deeper the problem, the more labour and materials are required.

- Repair Technique: A quick buff and recoat can often be done in a day. On the other hand, carefully lacing in new boards to seamlessly match an existing heritage floor is a true craft that takes time and skill, and the price reflects that.

Here in Australia, labour rates for a skilled flooring specialist typically fall between $30 to $50 per hour. As you can imagine, rates in Sydney are often higher than in regional areas. If you want to dig a bit deeper into what goes into a quote, you can find more detailed flooring repair estimates here.

Estimated Cost Comparison for Common Timber Floor Repairs in NSW

To give you a clearer picture, here’s a table outlining some ballpark figures for common repair jobs. It compares the rough cost of materials if you were to tackle it yourself versus the estimated price for a professional service, which includes labour, materials, and expertise.

| Repair Service | Average DIY Cost (Materials Only) | Estimated Professional Cost (Labour & Materials) |

|---|---|---|

| Fixing Squeaky Boards | $30 – $100 (Screws, glue, filler) | $250 – $600+ |

| Replacing 1-3 Damaged Boards | $80 – $250 (Timber, adhesive, finish) | $400 – $900+ |

| Minor Scratch & Gouge Repair | $50 – $150 (Wood filler, stain pens, polish) | $300 – $700+ |

| Sanding & Refinishing (per m²) | $10 – $20 (Sandpaper, finish, hire gear) | $40 – $70+ per m² |

| Major Rot or Termite Repair | Varies widely based on subfloor damage | $1,500 – $5,000+ |

Remember, these are just estimates. The final cost will always depend on the specifics of your floor and the extent of the work needed.

The "Location Tax": Labour and Logistics in NSW

Where your home is located plays a bigger role in the total cost than most people realise. It’s not just about differing labour rates between the city and the bush; for rural properties, the real challenge is logistics.

Getting the right people, specialist equipment, and specific timber boards out to a remote farm or a property down a long dirt road is a different ball game. Travel time, fuel, and the simple logistics of moving heavy machinery and materials all add up and will be factored into the final bill. It’s a crucial point to remember when comparing quotes from a local company versus one based hours away.

This chart gives a good overview of how a typical business in our industry breaks down its costs.

As you can see, the operational expenses—things like materials, fuel, and wages—make up a huge chunk of a flooring company's turnover.

Our Solution for Hard-to-Reach NSW Properties

Servicing properties scattered across the vast expanse of New South Wales takes more than just flooring expertise; it requires a purpose-built setup. That's why we’ve invested in a custom-built 10 tonne 4×4 truck, designed from the ground up to handle the access challenges that come with remote and rural work.

This truck is more than just transport—it’s our mobile workshop and warehouse on wheels. It’s kitted out to carry our whole team, all the timber and finishes we’ll need for the job, and every single piece of equipment, directly to your doorstep.

We’re geared to handle dirt tracks, creek crossings, and rugged country to deliver the same quality timber floor repairs you'd expect in the city, no matter how far out you are. This setup means we sidestep the delays and supply headaches that can derail projects in isolated areas. It ensures we can get your job done properly and efficiently, the first time. We bring the workshop to you.

Bringing Expert Floor Repairs to Remote NSW

Living out in rural or remote New South Wales comes with its own set of challenges, and getting quality tradespeople out to your property is often high on the list. The sheer distances can turn sourcing the right materials and skilled hands for timber floor repairs into a logistical nightmare. Too often, it means homeowners have to settle for a patch-up job or put up with frustrating delays.

We saw this problem firsthand and knew a standard city-based approach just wouldn't cut it. To do a job properly, whether you're on the coast or deep in the outback, you need more than just good skills—you need a setup designed to beat the tyranny of distance. That's exactly why we built our entire service around being self-sufficient and mobile.

Our promise is simple: to deliver the same high standard of craftsmanship to every single job, no matter how far off the beaten track you are. We’ve invested heavily in a system that gets around all the usual hurdles of working in regional NSW, so your floors get the professional attention they deserve.

Our 10-Tonne Mobile Workshop Solution

The key to it all is our custom-built, 10-tonne 4×4 truck. This isn't just a ute with a toolbox on the back; it's a complete mobile workshop designed to handle the harshest Australian conditions. It lets us carry everything we could possibly need for a full flooring project and bring it right to your front door in one trip. This allows us to bring in labour, materials, and equipment where and when it's needed the most.

This beast of a truck is an all-terrain vehicle built to handle pretty much anything. Winding dirt tracks, steep hills, creek crossings, and unsealed roads are all in a day's work. Its off-road capability means we can get to properties that would leave standard vans stranded, ensuring we can help you when you need it most.

We literally bring the entire workshop to you. This truck is loaded up with our skilled crew, all the timber and finishes, and every specialised tool needed to get the job done perfectly on-site.

Solving the Logistical Headaches of Rural Work

The real beauty of our mobile setup is how it cuts through all the red tape and waiting games that usually come with rural projects. By having everything on board from the get-go, we eliminate the common frustrations.

- No Waiting on Materials: We show up with all the timber, glues, and coatings needed for the job. That means no more waiting weeks for a special order to arrive at the local hardware store.

- The Right Tools, Every Time: From heavy-duty sanders to precision cutting tools, our team has everything at their fingertips. No corners are cut because we’re missing a piece of equipment.

- Getting the Job Done Efficiently: Because we’re fully self-sufficient, we can get started the moment we arrive and keep working without interruption. This keeps your project on track and minimises the disruption to your home.

This approach turns what could be a drawn-out, complicated ordeal into a smooth, predictable process. It means that whether you’re in Tamworth, out near Bourke, or on a station past Broken Hill, you get the same professional service and top-quality results. Our goal is to make expert timber floor repairs accessible to everyone in NSW, no matter where they call home.

Proactive Care to Protect Your Timber Floors

Once you’ve gone to the trouble of repairing your timber floors, the last thing you want is to be doing it all again in a few years. The smartest move is to shift from reactive repairs to proactive maintenance.

Think of it less as a chore and more as a simple routine that will protect your investment for decades. It's really about small, consistent habits that make a massive difference over the life of your floor. A little preventative care goes a long way in reducing wear and tear and keeping your floors looking as good as the day they were finished.

Your Essential Maintenance Checklist

The best way to stay on top of floor care is to build a simple routine. When you break it down into daily, weekly, and seasonal tasks, it becomes second nature and stops problems before they even start.

- Daily Sweep or Dust Mop: Your floor's worst enemy isn't heavy furniture; it's the tiny bits of grit and sand that get tracked in every day. Underfoot, this stuff acts just like sandpaper, slowly grinding away the protective finish. A quick daily run-over with a soft-bristle broom or a microfibre mop is the single most effective thing you can do.

- Weekly Damp Mop: Once a week, give the floors a proper clean with a damp—and I mean damp, not wet—mop. Always use a pH-neutral cleaner made specifically for timber, as anything harsher will strip the finish. Remember, excess water is timber’s kryptonite, so wring that mop out well.

- Wipe Up Spills Immediately: It happens. But letting a spill sit is just asking for trouble. Blot any liquids straight away with a dry cloth. This stops moisture from seeping into the grain and causing those ugly stains or, worse, swelling.

Also, do yourself a massive favour and stick protective felt pads on the bottom of all your furniture legs. It’s a cheap and simple fix that prevents countless deep scratches and gouges every time a chair is pushed back or a table is nudged.

Managing Your Indoor Environment

Timber is a natural product; it breathes and moves with the environment. Here in New South Wales, where we can get everything from coastal humidity to dry inland heat, controlling your home's indoor climate is crucial for preventing boards from warping, cupping, or gapping.

Try to maintain a consistent humidity level, ideally somewhere between 35% and 55%. In the muggy summer months, a dehumidifier can be a lifesaver, stopping boards from swelling. Conversely, in the dry winter, a humidifier can prevent them from shrinking and creating unsightly gaps. Good old-fashioned ventilation is also your friend, especially for keeping any subfloor areas dry.

A professional recoat every few years is one of the smartest long-term investments you can make. This involves lightly buffing the existing finish and applying a fresh topcoat. It restores the protective barrier without the cost and hassle of a full sand-and-refinish job. It’s preventative maintenance at its best.

Innovations in Floor Durability

Thankfully, the flooring industry doesn't stand still. New materials and finishes are coming out all the time that offer better durability and easier maintenance, which is great news for homeowners. For a deeper dive into modern building practices, our guide on property and building maintenance has some excellent insights.

One of the biggest trends in the Australian market is the shift towards advanced materials like engineered timber. It's become incredibly popular because its layered construction gives it far greater stability against moisture, making it perfect for our varied climate. It’s simply less prone to warping and shrinking than traditional solid hardwood, which means fewer repairs down the track. You can read more about these top timber flooring trends in Australia.

Many of these modern floors also come with high-performance surface coatings that are amazingly resistant to stains, spills, and scratches. That built-in toughness means you can spend less time worrying about your floors and more time actually enjoying your home.

For all your building and repair needs across regional New South Wales, trust the experienced team at Awesim Building Contractors. From minor repairs to major renovations, we have the skills and equipment to deliver exceptional results. Contact us today to discuss your project at https://awesim.au.

2 Comments