Your farm machinery is the engine of your livelihood. It's more than just steel and hydraulics; it's a massive investment that keeps your operation running, and a well-built shed is its first and best line of defence.

For anyone on the land in New South Wales, a quality machinery shed isn't just another cost—it's a critical investment in protecting your assets and directly impacts your bottom line.

Protecting Your Assets from the NSW Climate

The gear in your yard represents a huge capital outlay; it's the backbone of your entire operation. Leaving these high-value machines exposed to the harsh NSW climate is a gamble you can't afford to take.

From the relentless summer sun that fades paint and perishes hydraulic hoses, to corrosive rain and the fine, abrasive dust that gets into everything, the elements are constantly working to shorten the life of your equipment. A purpose-built machinery shed is the only real shield you have to preserve the value and reliability of your fleet.

This protection pays for itself, and then some. By keeping your equipment under cover, you're looking at fewer costly repairs, extending the machinery's working life by up to 40%, and significantly boosting its resale value when you decide to upgrade. It’s not just about keeping things clean; it’s a core part of smart asset management.

Reaching Every Corner of New South Wales

We know that some of the hardest-working farms are also the hardest to get to. It's why we've geared our entire service around solving the logistical headaches that stop other builders in their tracks.

Our specialised 10 tonne 4×4 truck is the key. It gives us the muscle to bring in all the necessary materials and supplies for the most remote properties around New South Wales. This capability allows us to bring in labour, materials, and equipment exactly where and when it's needed the most.

Whether your property is at the end of a long dirt track or involves a few water crossings, our logistical setup ensures your project moves ahead without a hitch. We're fully equipped to deliver the complete build, wherever you are.

The Growing Need for Secure Machinery Sheds

Secure storage has never been more important. Back in 2021, NSW broke all previous records for new tractor sales, with an incredible 5,442 units delivered to rural properties—a jump of 39% from the year before.

Without proper shelter, this influx of brand-new gear faces rapid wear from our tough climate, which can slash resale values by 20-30%. On top of that, industry data shows that unprotected machinery needs about 25% more maintenance, adding a significant cost over its lifetime. You can read the full industry report to get a clearer picture of the trends in agricultural machinery.

Designing a Shed That Works for Your Farm

A machinery shed is so much more than just a roof over your gear; it's the nerve centre of your entire farming operation. When you get the design right, it simplifies your workflow, makes maintenance a breeze, and ultimately, helps you get more done. The aim is to build a structure that works for you, not one you’re constantly having to work around.

The best way to start is by thinking about how you actually use your machinery day-to-day. A well-planned shed anticipates what you need, giving you easy access, plenty of room to swing a spanner, and the flexibility to adapt as your operation expands. It’s about creating a practical, hard-working asset that will support your farm for decades.

Matching the Layout to Your Operational Needs

The layout of your shed has a massive impact on how useful it is. There’s no single "best" design—it all comes down to your specific needs, the kind of gear you're running, and whether you need to include a workshop.

An open-front shed, for example, gives you brilliant accessibility for equipment you’re in and out of all the time, like your main tractor or the ute. On the other hand, a fully enclosed shed offers maximum security and protection from the weather, which is perfect for storing high-value assets like a harvester or setting up a dedicated workshop.

Choosing the right layout is your first big decision. You can check out a range of ideas in our detailed guide on custom farm shed design to see what’s working for other properties across NSW.

Sizing Your Shed for Today and Tomorrow

If there's one regret we hear from farmers, it's this: "I wish I'd built it bigger." It's absolutely critical to plan not just for the gear you have now, but for what you might have in five or ten years. Farm machinery isn't getting any smaller, so a bit of forward-thinking pays off big time.

Get the tape measure out and size up your biggest pieces of equipment—think of your combine with the header on, or an air seeder fully folded out. Then, add at least a few metres of breathing room on all sides. This extra space ensures you're not playing a high-stakes game of Tetris every time you need to move something.

Don't just think in two dimensions. Your shed's height is just as important as its footprint. Good clearance means you can easily tip a truck tray or lift machinery for repairs without worrying about clipping a roof truss.

Essential Features and Customisations

The small details are what really turn a standard shed into a high-performance workspace. Smart customisations tailor the building to your specific workflow, adding a huge amount of practical value.

Key features worth considering include:

- Integrated Workshop Bays: A lockable, enclosed bay inside the main shed gives you a secure, clean spot for maintenance, tool storage, or fabrication jobs.

- Mezzanine Floors: Adding a second level is a clever way to get spare parts, seasonal gear, and other supplies off the main floor, freeing up valuable real estate below.

- Ventilation and Lighting: Proper airflow stops moisture from building up, while translucent skylight panels slash your power bill by letting in natural light. It makes for a much safer and more pleasant place to work.

- Concrete Flooring: A reinforced concrete slab is a must. It gives you a durable, level surface that can handle heavy loads, stops machinery from getting bogged in the mud, and makes cleaning up oil or chemical spills a simple job.

Choosing the right doors is another decision that affects your daily routine. Sliding doors are a cost-effective choice for extra-wide openings, but they don't provide a perfect seal. Roller doors offer far better security and weatherproofing, making them ideal for workshops where keeping dust and vermin out is a priority. Your choice will come down to balancing accessibility, security, and your budget.

Choosing Materials That Stand Up to NSW Conditions

Your machinery shed is a long-term investment, and here in New South Wales, its lifespan really comes down to the quality of the materials you choose. From the blistering sun out on the western plains to the coastal humidity and sudden downpours, a shed built with cheap components just won’t go the distance. That’s why we’re staunch supporters of using premium, Australian-made materials built for our unique climate.

The backbone of any decent shed is its steel. We build exclusively with genuine Australian-made Colorbond steel for all our cladding and roofing. It’s about more than just the colour; Colorbond is engineered with layers of protection that resist chipping, peeling, and cracking. This means your shed will hold its own for decades, maintaining its structural integrity and looks even when battered by harsh UV and rain.

It’s a similar story with the timber. Any timber we use for structural components is properly treated to fight off termites and rot, two of the biggest threats for any rural building. By pairing a galvanised steel frame with high-grade, treated timber, we create a structure that’s incredibly durable and asks for very little maintenance, giving you one less thing to worry about.

Engineered for a Tough Climate

A shed is only ever as strong as its weakest link. We get that, so we focus on the critical structural details that aren’t always obvious. This ensures every part of your build is properly engineered to handle whatever the NSW climate decides to throw at it, starting right from the ground up.

The footings are, without a doubt, one of the most important parts of the whole build. We engineer the concrete footings specifically for your property’s soil type—whether you’re on reactive clay near the coast or sandy loam further inland. Getting this right from the start prevents the shed from shifting or sinking down the track, which is key to its long-term stability.

On top of that, every shed we design is engineered to meet or exceed the wind rating for your exact location. This is non-negotiable, especially for properties on exposed plains or ridgelines where the wind can really howl. Our engineering guarantees your structure stays put during severe storms, protecting the valuable gear you’ve got parked inside.

We don’t just tick the boxes for Australian Standards and local council codes; our goal is to go above and beyond. This approach gives you complete peace of mind that your investment is built to last, fully compliant, and truly engineered for the realities of life on the land.

Practical Add-Ons for a More Usable Shed

Beyond the frame and cladding, a few practical features can turn your machinery shed from a simple shelter into a genuinely functional and secure workspace. These additions are all about giving your equipment better protection and making those maintenance jobs a bit more comfortable and efficient.

One of the best additions you can make is insulation. Putting proper insulation in the roof and walls, especially if you have an integrated workshop bay, makes a world of difference. It keeps the space cooler in summer and warmer in winter, making it a far more productive place to be when you’re doing repairs or servicing machinery.

Vermin-proofing is another must-have. We make sure all potential entry points are sealed up tight to keep rodents and birds out. It’s a simple step, but it protects your electrical wiring, prevents damage to anything you’re storing, and keeps the whole space cleaner and safer for your valuable equipment. These are the thoughtful details that make a shed a truly workable part of your farm’s infrastructure.

After all, unprotected gear in dusty conditions often leads to 25-40% higher maintenance costs. Given that the heavy machinery repair sector in Australia is a $22.7 billion industry, anything you can do to reduce wear and tear pays off. You can read more on how proper storage impacts repair bills in this detailed industry analysis.

Navigating the Build Process From Start to Finish

Getting a new machinery shed shouldn't be a source of stress or disruption to your daily work. The whole point is to make life easier. We see the build process as a straightforward journey, one where you’re kept in the loop from the first chat right through to the day we hand over the keys. It all comes down to getting the foundations right—both literally and figuratively.

It starts with thinking carefully about site selection and preparation. This first step is absolutely crucial for the long-term integrity and usefulness of your shed. We can offer some hard-won advice on where to position the structure to make the most of natural drainage, guarantee all-weather access for heavy gear, and make sure it slots neatly into your existing farm layout.

Your Build Journey Step by Step

Once we've pinpointed the perfect spot, the build itself gets underway. Every stage is planned out to keep things moving along smoothly and on schedule. Because we manage the entire project from end-to-end, you’re free to get on with running your property while we handle all the details.

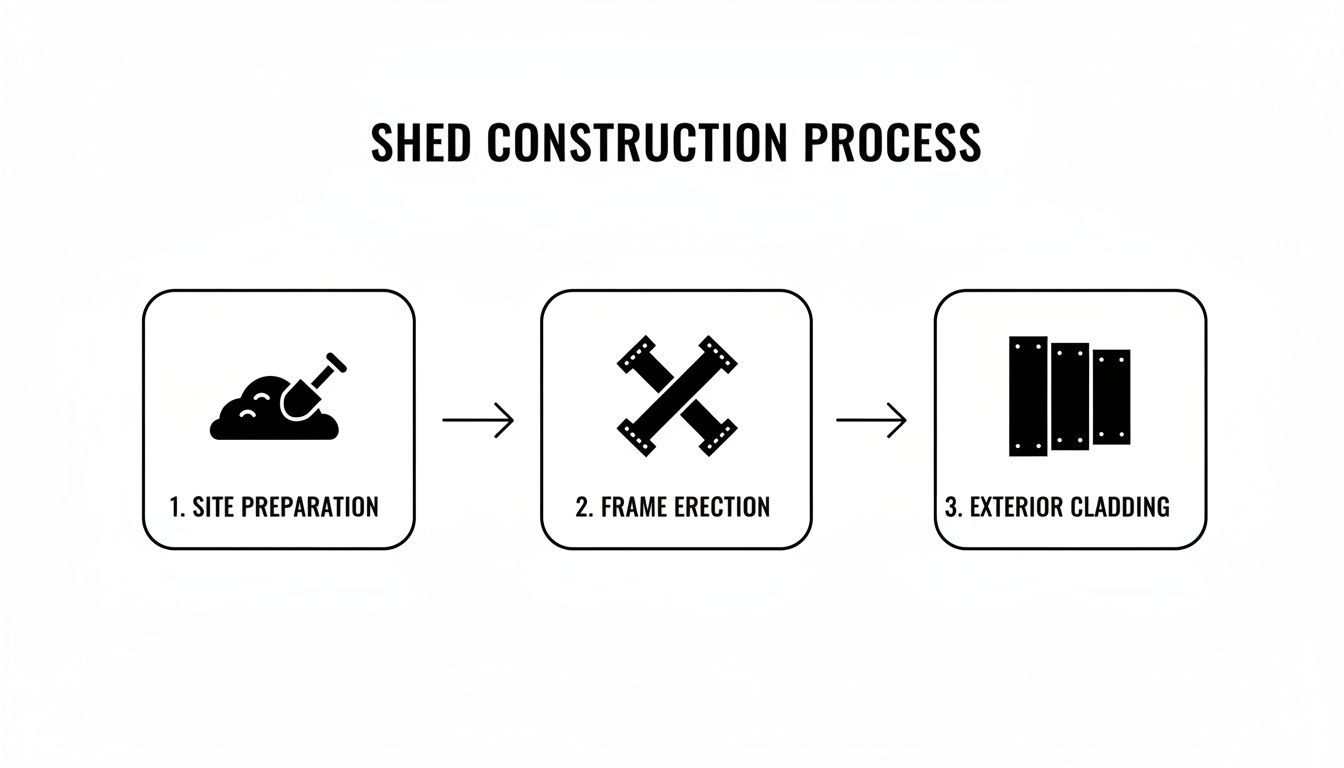

Here’s how a typical build unfolds with us:

- Initial Consultation and Design: We kick things off by listening. We need to understand your exact needs—from the dimensions of your biggest header to your workshop requirements—so we can design a shed that truly works for you.

- Council Approvals: Let's be honest, nobody enjoys paperwork. We take care of the entire council approval process to ensure your build is fully compliant from day one. You can find out more about whether you need council approval for a shed in our detailed guide.

- Site Preparation and Foundation: This is where the earthworks happen. We pour a reinforced concrete slab that’s engineered specifically for your soil type and the weight of your machinery, creating a rock-solid base.

- Frame Erection and Cladding: Next, the structural steel frame goes up. This is quickly followed by the Australian-made Colorbond steel for the roof and walls, bringing the structure to life.

- Final Fit-Out and Handover: We install the doors, windows, guttering, and any other custom bits and pieces. After a final inspection to make sure everything is perfect, we hand over the keys.

This infographic breaks down the main construction phases, from preparing the ground to putting up the frame and finishing with the cladding.

Each step is a building block for the next, resulting in a machinery shed that's built to last.

Delivering to the Most Remote NSW Properties

One of the biggest headaches with any rural construction project can be logistics. Getting materials, equipment, and a skilled crew out to remote properties across New South Wales can lead to frustrating delays and blowouts. This is where we’ve really invested to make sure that never happens.

We run a purpose-built 10-tonne 4×4 truck, backed up by a fleet of 4×4 utes. This heavy-duty setup is our promise that we can get to your property, no matter how far off the beaten track you are. From the flat country around Dubbo to the red dirt out past Broken Hill, a tricky access road is never a dealbreaker for us.

Our specialised truck means we can bring everything we need directly to your site in one go. We’re used to navigating dirt tracks, creek crossings, and rugged country to get materials and tools where they need to be, right on time.

This logistical muscle means we can deliver the same high-quality build anywhere. We handle the challenge of remote access so you don't have to.

Preparing Your Site For Construction

Before a single bag of concrete is mixed, the site needs to be properly prepared. This usually means clearing the designated area to create a clean, level pad for the shed to sit on. How much work is involved really depends on what the patch of land looks like to begin with.

It's a good idea to get your head around understanding the land clearing process before work begins. Getting this part right is non-negotiable; it prevents a world of future pain with drainage and stability, giving your shed the solid footing it needs to stand strong for generations.

Getting to Grips with Machinery Shed Costs

Investing in a new machinery shed is a major decision, and getting the numbers right from the start is absolutely crucial. The final cost isn't just one single figure; it’s a mix of different elements, and understanding what drives the price up or down will help you create a realistic budget. Think of it less as an expense and more as a long-term investment in protecting your most valuable farm assets.

The total price comes down to a combination of materials, the labour involved, what your site is like, and any extras you decide to include. Every choice you make, from the shed's overall size to the type of roller doors you hang, will have an impact on the final invoice. Let's break it down so you can see exactly where your money goes.

Key Factors That Shape the Price

So, what are the main things that determine the final cost of a machinery shed? You can think of these as levers you can pull to match the build to your budget and what you need it to do. Knowing what they are helps you make smarter decisions for the long haul.

Here’s what really moves the needle on price:

- Shed Size and Layout: It’s simple, really. A bigger footprint or a more complex design—like one with multiple bays or an enclosed workshop—means more materials and more labour, which bumps up the cost.

- Choice of Materials: When you choose premium, Australian-made materials like genuine Colorbond steel, it’ll cost more upfront than some cheaper alternatives. The trade-off? You get a shed that stands up to the tough NSW climate for years to come.

- Custom Features and Fit-Out: This is where you can really tailor the shed to your operation. Things like insulation, mezzanine floors for extra storage, heavy-duty concrete slabs, and automated doors will add to the initial cost but can make a world of difference to how the shed functions day-to-day.

- Site Prep and Access: A nice, flat, easy-to-reach block is always going to be cheaper to work with. If your site is on a slope, is rocky, or is way out in the backblocks, you’ll need to factor in more time and money for earthworks and logistics.

Getting materials and crew to remote properties can be a real headache, but it's something we've got sorted. We run a purpose-built 10 tonne 4×4 truck specifically for those hard-to-reach jobs across New South Wales. It allows us to bring everything we need—labour, materials, and equipment—right to your doorstep, keeping the project moving and avoiding the costly delays that bad access can cause.

Budgeting for Your New Shed

A good chunk of your budget will go into the foundation, and for good reason. A solid concrete slab is non-negotiable when you’re dealing with heavy machinery. Getting a handle on current shed foundation costs is a great first step in putting together an accurate budget.

Here’s a look at some typical cost ranges to help you get a feel for the investment. Keep in mind these are estimates, as the final price will depend on your specific site, design, and features.

Estimated Cost Ranges for Machinery Sheds in NSW

| Shed Size Category | Typical Dimensions (m) | Estimated Cost Range (AUD) |

|---|---|---|

| Small | 12m x 7m x 4.5m | $40,000 – $70,000 |

| Medium | 24m x 12m x 5m | $80,000 – $150,000 |

| Large | 36m x 18m x 6m | $160,000 – $300,000+ |

Remember, putting money into a quality shed now can save you a fortune down the track. With Australia's agricultural machinery market expected to hit USD 7.62 billion by 2031 and some growers facing machinery running costs of USD 686 per hectare, protecting that gear is vital. A good shed can extend the life of your machinery by up to 40%, helping farmers from Parkes to Moree avoid crippling repair bills and downtime.

By planning smart, you can focus your budget on the features that will give you the best bang for your buck. For a more detailed guide, have a read of our article on the cost to build a storage shed right here in NSW.

Your Machinery Shed Questions Answered

Putting up a new machinery shed is a big investment for any farm, so it’s only natural to have a few questions before you get started. With over 35 years of building sheds right across New South Wales, we've heard just about every question there is. Here are some clear, straight-to-the-point answers to the things we get asked most often.

We want you to feel confident moving forward, knowing your project is in the hands of a team that genuinely understands life on the land.

Do I Need Council Approval for a Machinery Shed in NSW?

Yes, almost always. In NSW, most farm buildings—machinery sheds included—will need a green light from the local council. This is usually done through either a Development Application (DA) or a Complying Development Certificate (CDC), and which one you'll need depends on your property's zoning and the shed's size.

Don't worry about the paperwork, though. We handle the entire council process for you, from drafting the plans and getting the documents in order to lodging the application and talking with council staff. We make sure your build is compliant right from day one.

How Long Does It Take to Build a Machinery Shed?

Every project is a bit different, but they all follow a similar path. You can generally break it down like this:

- Design & Approvals: This part usually takes between 4-12 weeks.

- Material Fabrication: Once approved, we get the steel made, which takes another 3-6 weeks.

- On-Site Construction: With everything delivered, the build itself can take anywhere from 2-8 weeks.

We'll give you a detailed schedule right at the start, so you always know what's happening and when. A big part of how we stick to that timeline is our purpose-built 10-tonne 4×4 truck, which lets us get materials to even the most out-of-the-way sites without the usual delivery headaches.

What Is the Best Foundation for a Heavy Machinery Shed?

For a shed that’s going to house heavy gear, you can't go past a reinforced concrete slab. It’s the industry standard for a good reason. It gives you an incredibly strong, level, and long-lasting base that’s properly engineered to handle the serious weight of today’s headers, tractors, and air seeders.

The thickness of the slab and the amount of reinforcing steel isn't just a guess—it's all calculated based on your soil conditions and the specific equipment you plan to store. We look after the whole concreting job, from digging out and setting up the formwork to the final pour, making sure it's built to Australian Standards and made to last.

Can You Build on My Remote Property with Difficult Access?

Absolutely. Getting to remote and tricky-to-access properties is what we do best—it’s a massive part of our business. We know that some of the most productive farms in NSW aren't exactly on the beaten track.

We’re fully set up to tackle challenging terrain. Our fleet includes a purpose-built 10-tonne 4×4 truck that can handle just about anything you throw at it. Navigating dirt tracks, creek crossings, and isolated properties is all in a day's work for us. No matter where you are in New South Wales, we’ll get the crew, materials, and equipment there, right on time. Your location is a challenge we're ready for, not an obstacle.

At Awesim Building Contractors, we build tough, high-quality machinery sheds designed to handle the harsh conditions of rural NSW. If you’re ready to protect your valuable gear with a shed that’s built for your specific needs, contact us today for a consultation.