Building in the outback isn't for the faint of heart. It takes a special kind of builder, one who understands that constructing, renovating, or repairing a property in a remote area is a completely different ball game. These aren't your typical city builders; they're logistical experts who thrive on tackling harsh weather, extreme distances, and tough-as-nails terrain. What it takes to be a builder in the outback is more than just skill; it’s about resilience against hot weather, the difficulty of access with bull dust on roads, water crossings, and rough terrain. Their success isn't just about building well—it’s about planning meticulously and having the right gear to get the job done where others can't.

The Unique Challenges of Outback Construction

Putting up a structure in regional New South Wales is far more than just dealing with a few extra kilometres. It's a specialised discipline that calls for grit, deep local knowledge, and seriously heavy-duty equipment. The standard methods that work perfectly in a suburban setting can fall apart spectacularly when they meet the realities of the Australian bush.

The environment itself is your first and biggest opponent. Blistering summer heat can halt work midday for safety reasons and play havoc with materials like concrete as it cures. Then, a sudden downpour can transform a dry creek bed into a raging river, completely cutting off your site for days on end.

Navigating Unpredictable Terrain

Often, the biggest battle is just getting there. The roads to many rural properties are unsealed and constantly throwing up new obstacles. We're not talking about simple gravel tracks; these routes can be rugged and truly unforgiving.

- Bull Dust: This isn't just dirt. It's a fine, powdery dust that can be metres deep, hiding massive potholes and swallowing conventional vehicles in a heartbeat. It takes a skilled driver and the right kind of truck to get through.

- Water Crossings: Seasonal creeks and rivers can flood with almost no warning, making site access a gamble. A builder has to know the local landscape intimately and have a vehicle that can safely ford water when needed.

- Rough Ground: Corrugated roads and rocky patches can shake a standard vehicle to bits, causing damage to both the truck and the equipment it's carrying.

These conditions make getting your crew, materials, and machinery to the site the single greatest challenge of the entire project. A delayed delivery of steel frames or a team of carpenters stranded on the wrong side of a creek can bring everything to a grinding halt, costing you precious time and money.

To put it into perspective, here's a quick look at how different the worlds of urban and outback construction really are.

Outback vs Urban Construction Key Differences

| Challenge | Urban Construction | Outback Construction |

|---|---|---|

| Material Sourcing | Multiple local suppliers, easy next-day delivery. | Single distant supplier, weeks of lead time needed. |

| Site Access | Paved roads, predictable access year-round. | Unsealed tracks, bull dust, river crossings, seasonal closures. |

| Labour Availability | Large pool of local tradespeople and contractors. | Limited local specialists; requires bringing in a skilled team. |

| Equipment | Standard vehicles and machinery are sufficient. | Requires 4x4s, heavy-duty trucks, and all-terrain vehicles. |

| Weather Impact | Delays are usually minor and short-lived. | Extreme heat, floods, or fires can shut down a project for days or weeks. |

| Contingency | A small buffer for unexpected issues is typical. | Requires extensive planning for logistical failures, material shortages, and access problems. |

As you can see, an outback builder's checklist looks a whole lot different. It's all about proactive planning for things that an urban builder would never even have to consider.

The success of an outback build hinges on one critical factor: reliable logistics. Without a solid plan and the right equipment to overcome access issues, even the best-laid plans will fall short.

Our Solution to Remote Access

We knew from day one that logistics would make or break our projects. That’s why we invested in a purpose-built 10-tonne 4×4 truck. This isn't just a delivery vehicle; it's a mobile base of operations engineered to conquer the toughest conditions rural NSW can serve up.

This beast of a truck lets us be completely self-sufficient. We can load it up with a full crew of trades, tonnes of building materials, and all the essential equipment needed, then get it all to your property in one reliable trip. It gives us the power to get in and out of the most isolated properties around Bourke, Cobar, Moree, Dubbo, and beyond.

By handling our own transport, we cut out the reliance on third-party freight companies that often lack the right vehicles or the experience to navigate outback tracks. This means we bring everything—labour, materials, and machinery—exactly where it needs to be, right when it's needed, keeping your project on track no matter what the terrain throws at us.

Finding a Builder Who Understands Rural NSW

Choosing the right builder for a project out in the bush is about much more than just ticking boxes on a licence check or browsing a slick photo gallery. When you’re building remotely, a builder's most critical assets are their firsthand experience with the unique challenges of your area and the heavy-duty logistics to back it up.

A pretty portfolio doesn't mean a thing if they can’t handle a flooded creek crossing or a track that’s turned to impassable bull dust. You need a team that has not only worked in places like Bourke, Cobar, Moree, and Dubbo but truly gets the demands these environments place on people, materials, and machinery.

A genuine outback builder doesn't just put up sheds and homes; they run complex, isolated operations where every single detail has to be planned weeks, sometimes months, in advance.

Vetting for True Outback Expertise

When you start talking to potential builders, your questions need to get straight to the point. You've got to cut through the sales pitch and find out if they have what it takes to handle the realities of building in rural NSW. The difference between a smooth project and a costly, drawn-out nightmare often comes down to this.

Get started with these essential questions:

- "Can you show me projects you've finished near my property?" Ask for specific examples of jobs they've done in similar remote conditions, not just in regional centres.

- "How do you manage transporting materials and your team?" This is a big one. Do they have their own heavy-duty vehicles, or are they relying on third-party freight companies that might not know the area?

- "What's your plan for weather delays?" Any builder worth their salt will have a clear strategy for dealing with extreme heat, fires, or flooding without derailing the whole project.

Their answers will quickly tell you who the real specialists are. You're looking for someone who can talk confidently about navigating local challenges because they've done it time and time again. For more on this, our detailed guide on how to choose a builder is a great resource.

The Logistical Advantage: Our 10-Tonne 4×4 Truck

At Awesim, we know from experience that logistics is the number one point of failure for remote building projects. It’s why we invested in our own 10-tonne 4×4 truck. This beast is our commitment to getting our crew, your materials, and all our equipment to even the most inaccessible sites, no matter the conditions. It allows us to get in and out of most rural properties.

Having our own heavy-duty transport isn’t a nice-to-have; it's fundamental to how we operate. It means we can haul everything needed for the job in a single, reliable trip. We’re not at the mercy of outside carriers, and that’s how we keep your project on schedule.

This self-sufficiency is what it really takes to build in the outback. It’s about more than construction skills—it’s about having the right gear to conquer the immense challenges of distance and terrain.

Industry Growth and Local Impact

The need for skilled outback builders is growing right alongside the national construction industry, which is forecasted to expand by 3.8% in 2025. Major engineering and infrastructure projects are driving this growth, and the ripple effect is felt in rural areas, boosting demand for everything from new farm sheds to homestead renovations. You can read more on the trends shaping Australia's construction market and see how they influence regional development.

This momentum makes it even more critical to partner with a builder who has the right experience and equipment. A builder with proven logistical capabilities, like our 4×4 truck, is far better positioned to manage the pressures of a busy market and deliver your project on time and on budget, even in the most remote corners of NSW.

Solving Remote Access and Logistics

https://www.youtube.com/embed/OabUR3v5I1s

When you're building in the outback, the success of your project often has less to do with the blueprints and more to do with the bulldozer tracks leading to your site. Logistics isn't just a line item on a quote; it's the absolute foundation of the entire job. Get it wrong, and you're looking at crippling delays, budget blowouts, and a whole lot of frustration.

Honestly, the simple act of getting materials, equipment, and a skilled crew to a remote property is where most projects fall over before a single post hole is even dug. It’s the single biggest hurdle that separates a true outback builder from the rest. You're in a constant battle with the environment, and you need a strategy to win.

The Unforgiving Nature of Outback Access

Your average delivery truck or trade ute just isn't cut out for the realities of rural New South Wales. The trip to a remote station is often an obstacle course that can bring the most well-thought-out plan to a grinding halt.

Picture a property a few hours past Bourke or Cobar. The "road" might be little more than a dirt track, turning to fine, deep bull dust in the dry and a slick, impassable quagmire after a bit of rain. That bull dust is notorious for hiding deep ruts and washouts that'll swallow a conventional vehicle in a heartbeat.

Then you've got the water crossings. A dry creek bed can become a flowing river in just a few hours, completely cutting off your site. An experienced outback builder knows this rhythm, but knowing isn't enough. You need the right machinery to push through when a critical delivery is on the line.

Logistics in the outback is a high-stakes game. Relying on third-party freight services is a gamble many property owners end up losing. A standard courier might get your materials to the nearest regional hub like Dubbo or Moree, but that last, brutal leg of the journey is where it all falls apart.

Our Purpose-Built Logistical Solution

We saw this weak link in the chain time and time again, so we engineered our own solution from the ground up. We invested in a heavy-duty 10-tonne 4×4 truck, a beast designed specifically to conquer the terrain that stops everyone else. This truck is the backbone of our logistics and our promise to you that your build won't be derailed by a washed-out track.

This isn't just about owning a bigger truck; it’s about controlling the entire supply chain. It means we're completely self-sufficient. We bring everything—the crew, the materials, the gear—to your property in one go.

- Labour Deployment: We can move our whole team at once, so skilled tradies arrive on-site ready to work, not waiting around for a separate ride.

- Material Haulage: Tonnes of steel frames, Colorbond sheeting, concrete mix, and treated timbers all come in a single, secure trip, protected from the punishing outback roads.

- Equipment Transport: From generators and welders to specialised tools, it all arrives with us. No more delays waiting for a separate hire company to make a delivery.

By taking charge of our own logistics, we cut out the middleman and the uncertainty. We aren't waiting for a call from a freight driver stuck on the wrong side of a flooded creek near Moree. We're the ones driving through that creek to keep your project on schedule.

Real-World Scenarios We Conquer

The value of our 4×4 truck really hits home when you think about real-world situations. Let's say you need a full load of structural steel for a new machinery shed on a station past Cobar. A storm rolls through, and now the access track has a few low-level water crossings. A standard flatbed truck is stuck, waiting for days, and every one of those days costs you time and money. Our truck is built for that. It'll ford the water, power through the mud, and get that steel delivered so the work can continue.

Another classic scenario is the choking bull dust on the tracks leading to properties around Bourke. A conventional truck can easily get bogged or suffer a mechanical failure as the dust works its way into everything. Our 4×4 system gives us the traction to push through, and its robust build protects the important parts, ensuring we always get there.

This logistical independence is what makes us a leading rural building company. It gives you peace of mind, knowing your project’s success isn’t being left to chance or the weather. By solving the access problem first, we lay a solid foundation for a smooth, efficient, and successful build, no matter how far off the beaten track you are.

Choosing Materials That Outlast the Elements

Building in the outback isn't just about putting up walls and a roof; it's a battle against the elements. You're up against blistering sun, torrential rain, abrasive dust, and a whole host of pests looking for their next meal. Your choice of materials is less about aesthetics and more about pure survival.

Get this part wrong, and you're signing up for a future of constant repairs and maintenance headaches. Any builder worth their salt out here knows that you have to build it right the first time, using materials proven to handle the toughest conditions Australia can throw at them. This is one area where you simply can't afford to cut corners.

Shielding Your Structure with Steel

When it comes to roofing and cladding, there's really only one conversation to be had: genuine Australian-made Colorbond steel. Its reputation is rock-solid for a reason. This isn't just painted metal; it's a specialised system built to endure decades of abuse.

The baked-on finish is engineered to resist chipping and peeling under UV exposure that would cook standard paint right off. It also provides fantastic corrosion resistance, which is vital when a combination of dust and moisture can eat through lesser-quality steel. For sheds, homes, or any outbuilding you want to see standing in 20 years, it’s the default choice.

Building a Foundation That Fights Back

Underneath that tough steel skin, the frame is facing a different enemy: termites. These pests are a constant, silent threat across rural New South Wales and can hollow out a building's timber skeleton before you even know they're there. Using untreated pine or standard hardwood is basically laying out a welcome mat.

This is why we only use properly treated timbers for structural work. It’s a non-negotiable.

- H4 Treated Pine: This is your baseline for any timber touching the ground, like posts for a verandah or a shed. The treatment gives it a solid defence against both rot and termites.

- H5 Treated Pine: When you've got critical posts going directly into the ground where moisture is a constant, you need to step up to H5. It offers a higher grade of protection, ensuring the very foundation of your structure stays put.

Paying a little extra upfront for properly treated timber is cheap insurance. The alternative is risking the structural integrity of your entire build, and that's a gamble you will eventually lose.

An outback structure is only as strong as its weakest component. Investing in premium, climate-appropriate materials like Colorbond steel and H5 treated timber isn't an expense—it's insurance against the relentless forces of nature.

Smart Design for a Harsher Climate

Great materials are only half the story. Smart design is what really makes a building work in this environment. For instance, the simple orientation of a house can make a world of difference to how hot it gets inside. A good builder will always think about positioning the structure to shield it from that brutal western sun, which can dramatically cut down your cooling bills.

Water management is just as crucial. It’s not enough for a roof and gutter system to just get rid of water; it should be designed to capture every precious drop for your tanks. These are the kinds of practical details that turn a standard building into a truly resilient and sustainable outback property.

This focus on durable infrastructure is happening on a larger scale, too. The latest figures show that construction work across Australia rose 3.0% in the June 2025 quarter, with a significant 6.1% jump in engineering projects for essentials like water and energy. If you're interested, you can take a look at these nationwide construction trends to see the bigger picture. By choosing the right materials and design from the start, you're not just putting up a shed; you're creating a valuable, long-term asset.

From the First Quote to the Final Handover: Managing Your Outback Build

A successful outback build is founded on rock-solid communication and planning, long before a single post hits the ground. Getting your project from the initial quote to the final handover is all about having a transparent process that respects the unique challenges of building in remote New South Wales.

It all kicks off with the quote. A quote from a genuine outback builder should be a world away from a vague, one-page estimate for a suburban job. It needs to transparently break down the real logistical costs—mobilisation, freight for every single material, and accommodation for the crew. A fuzzy quote is a major red flag. You need an itemised breakdown that proves the builder has actually thought through the specifics of getting everything to your site, whether you're near Bourke, Cobar, or Dubbo. For a clearer picture of what to expect, you can estimate house construction costs with our detailed guide.

Setting Up a Clear Line of Communication

When your property is hours away, you can't just swing by the site to see how things are tracking. This is where crystal-clear communication protocols become non-negotiable. An experienced remote builder gets this and will already have a system ready to go.

Before they even start, agree on a communication schedule. This isn't about being difficult; it's about staying connected. A good system might include:

- Weekly Photo Updates: A few quick snaps sent via email or text are worth a thousand words. They give you visual proof of progress and make it easy to spot anything that needs a decision.

- Scheduled Phone Calls: Lock in a set time each week for a call. It means you have a dedicated slot to chat through progress and ask questions without endless games of phone tag.

- A Single Point of Contact: Nothing’s worse than being bounced around. Knowing exactly who to call cuts through the confusion and gets you straight, timely answers.

This kind of structured approach keeps you firmly in the loop, giving you peace of mind and ensuring you’re in control, no matter how many kilometres separate you from the build.

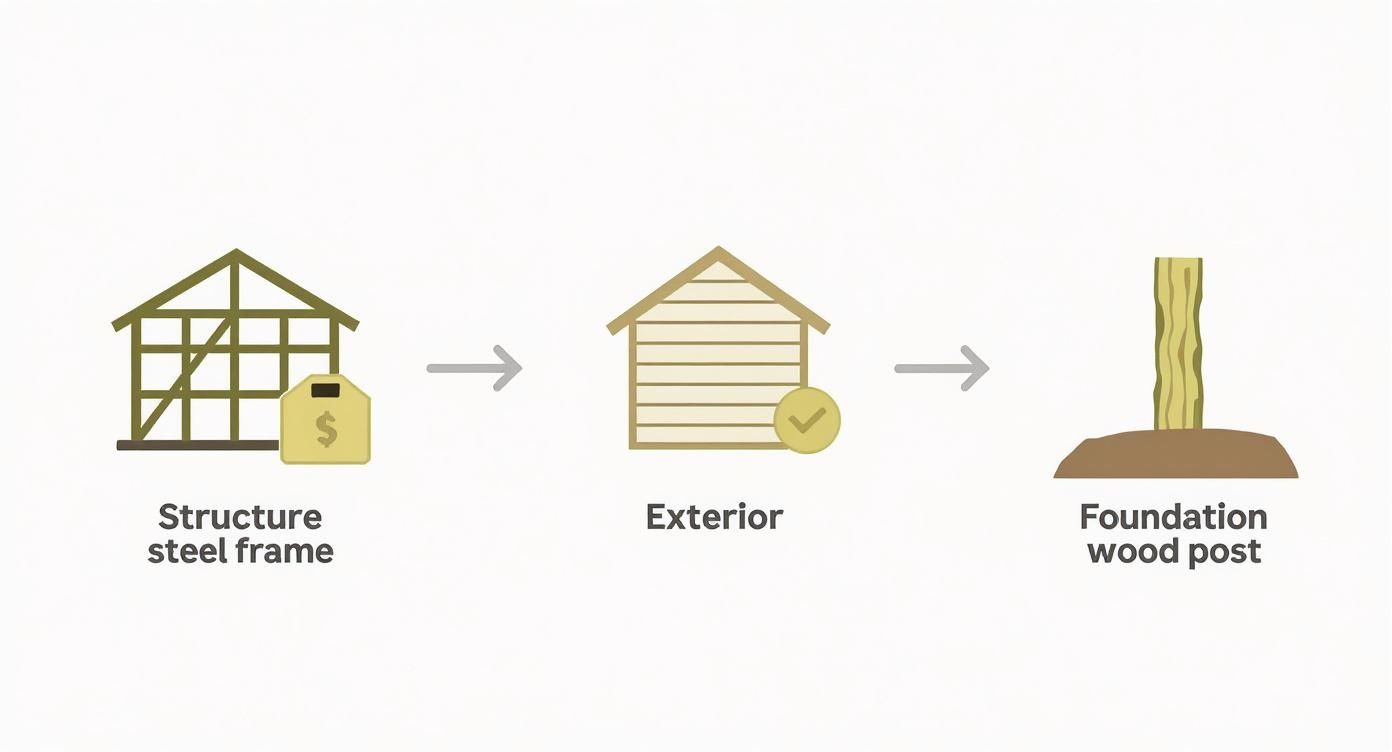

This visual guide shows the typical flow of materials for a remote project, from the bones of the structure to the final cladding.

It really highlights just how critical that upfront planning is to make sure every major component lands on-site in the right order.

Dealing with Timelines and Inevitable Delays

Out here, project timelines are always written in pencil, never in ink. A good builder will give you a realistic schedule, but everyone involved has to accept that Mother Nature often has the final word. A week of scorching 45-degree heat can bring work to a standstill for safety reasons, just as a sudden downpour can turn access roads into impassable bog holes for days.

A seasoned outback builder doesn't just react to these things; they plan for them. They watch the weather forecasts like a hawk and will strategically schedule crucial deliveries, like concrete pours or the arrival of the steel frame, for when conditions look most favourable. It’s this kind of proactive thinking that minimises the blow when delays inevitably happen.

The Final Handover: All About Compliance and Quality

The final leg of the journey is arguably the most important. This is where your builder ties up every loose end, ensuring the entire build meets Australian Standards and ticks every box for the local council.

The handover is more than just getting the keys. It’s the builder’s final promise of quality, a guarantee that the structure is fully compliant, safe, and ready to stand up to whatever the outback throws at it for decades.

This last phase involves final inspections, gathering all the necessary compliance certificates, and doing a thorough walk-through of the finished job with you. A professional handover is the mark of a true expert, leaving you with a durable, compliant, and top-quality asset that adds real, lasting value to your property.

Your Questions Answered: Outback Building in NSW

Building in the outback is a different beast altogether. It’s more than just construction; it's a test of grit, planning, and a genuine understanding of the land. The challenges out here are unique, and they shape every decision a true outback builder makes.

The weather is probably the most unforgiving boss you’ll ever have. With summer temperatures regularly climbing past 45°C, working through the middle of the day isn't just tough—it's downright dangerous. We often have to run on "outback time," starting at sunrise and knocking off early to beat the heat, which is something that has to be factored into any project schedule.

Getting There is Half the Battle

Simply reaching a remote property can be the biggest hurdle. The roads leading to properties around Bourke, Cobar, and Moree are a world away from sealed city streets. They're often just rugged tracks that can turn against you in an instant.

- Bull Dust: This stuff is notorious for a reason. It's a fine, talc-like powder that conceals deep ruts and can bog down a standard ute in seconds. It also works its way into every crevice of a vehicle, demanding relentless upkeep.

- Water Crossings: A sudden downpour can transform a dry creek bed into a raging river, effectively cutting a site off from the world for days. You learn to watch the sky and the weather maps very closely.

- Rough Terrain: Corrugated dirt roads and rocky tracks will shake equipment and materials to bits if you're not careful. This is why you need specialised, heavy-duty transport to ensure everything arrives on-site in one piece.

An outback builder has to wear many hats: logistician, mechanic, and amateur meteorologist. It’s all about anticipating what could go wrong and having a plan B, C, and D ready to go. You need a certain resilience to not just survive these conditions but to actually get the job done right.

How We Tackle Remote Logistics

We knew from the start that standard vehicles wouldn't cut it. That's why we invested in our own purpose-built 10-tonne 4×4 truck. It's our answer to the logistical puzzle of remote building, allowing us to bring in labour, materials and equipment where and when it's needed the most for the most remote properties around New South Wales. Think of it as our guarantee that we can reach your property when others simply can’t.

Having our own heavy-duty 4×4 truck means we're not at the mercy of third-party freight companies that don't have the right gear or the local know-how. We're in complete control of our own supply chain, which is absolutely vital for keeping a project on track.

This rig lets us load up everything we need—our crew, materials, and tools—and get it all to your site in one go. Whether we’re navigating a dusty track near Dubbo or picking our way across a seasonal creek, our truck is built for it. This self-sufficiency is key to ensuring your project keeps moving forward, no matter how far off the beaten track it is.

Frequently Asked Questions

How does the cost of building in the outback compare to a city?

It’s no secret that building remotely tends to be more expensive per square metre. The main drivers are logistics and labour. Every single item, from the steel frame down to the last screw, has to be trucked in, and that freight costs money. Finding and accommodating skilled tradespeople in places like Bourke or Cobar also adds to the budget. There’s no running down to the local hardware store if you forget something.

What happens if bad weather cuts off site access?

This is where experience truly makes a difference. A seasoned outback builder is constantly watching the weather and scheduling work and deliveries around it. While our 10-tonne 4×4 can get through conditions that would stop most vehicles, safety is always the priority. A good builder will have buffers built into the project timeline for weather delays and will keep you in the loop if the site becomes inaccessible due to something serious like a flood.

At Awesim Building Contractors, we have the experience, the team, and the right equipment to bring your rural building project to life. Contact us today to discuss your project.

1 Comment