When you start looking at machinery sheds prices, you'll find the numbers can swing quite a bit. A smaller, more straightforward shed might come in around $85,000, while a large, fully-customised build could easily push past $170,000. Getting a handle on these typical brackets is the best place to start planning your project, as the final figure really comes down to size, materials, and the unique conditions of your property.

Your Quick Guide To Machinery Shed Prices In NSW

Putting up a new machinery shed is a major investment for any rural operation in New South Wales. It’s not just about putting a roof over your gear; it's about protecting expensive equipment from the harsh Aussie climate, streamlining your workflow, and ultimately, safeguarding your livelihood.

But let's be honest, the first question on everyone's mind is always the same: what's this actually going to cost me?

Here at Awesim, we believe in being upfront from the get-go. With over 35 years of hands-on experience building sheds across NSW—from the black soil plains of Moree to the rugged country out near Bourke—we know that a clear picture of the costs is crucial before you even think about picking up the phone.

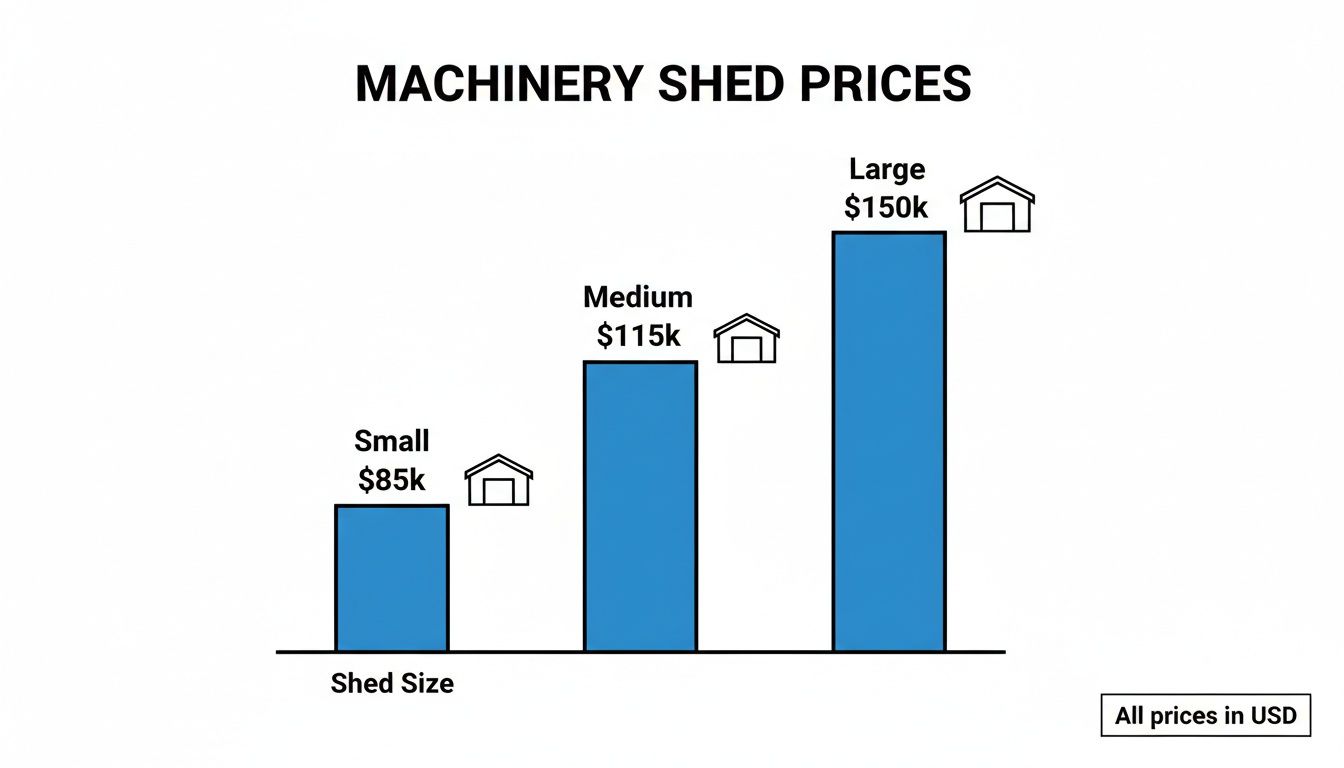

Typical Price Ranges For Common Shed Sizes

To give you a realistic idea of what to budget, we can look at some common shed sizes and their installed costs. These aren't just numbers plucked from thin air; they reflect real-world projects right here in NSW.

Typical Machinery Shed Price Ranges In NSW (Installed)

| Shed Dimensions (L x W x H) | Shed Type | Estimated Price Range (Inc. GST & Construction) |

|---|---|---|

| 24m x 15m x 5m | Fully Enclosed | $105,000 – $130,000 |

| 32m x 18m x 6m | Open Front | $95,000 – $120,000 |

| 40m x 21m x 6m | Open Front | $135,000 – $165,000 |

| 40m x 21m x 6m | Drive-Through | $140,000 – $170,000 |

These figures give you a solid ballpark to work with. For a deeper look into what drives these numbers, you can explore more about our farm shed prices.

Of course, that final price tag is a sum of several parts, and we’ll break each one down in this guide:

- The Shed Kit: The steel itself. We only use Australian-made materials, like high-tensile BlueScope and Colorbond steel.

- Labour & Construction: The cost for our experienced crew to put it all together correctly.

- Site Preparation: The earthworks needed to get your site level and ready.

- Concrete Slab: The foundation that ensures your shed stands the test of time.

- Delivery & Logistics: Getting all the materials and equipment out to your property.

Reaching The Most Remote NSW Properties

One of the biggest variables in any rural build is logistics. Getting materials, machinery, and a skilled crew out to remote properties can add significant—and often unexpected—costs to a project. This is one area where our experience really makes a difference.

We run a specialised 10-tonne 4×4 truck that was custom-built to handle the unique challenges of rural NSW. It allows us to bring in labour, materials, and equipment where and when it's needed the most, reaching even the most remote properties around New South Wales.

This capability means we can efficiently service some of the most isolated properties around Walgett, Broken Hill, and beyond. It’s how we ensure your project stays on schedule and on budget, without the logistical headaches. Understanding the cost to build a storage shed means accounting for everything, and our ability to manage remote delivery is a huge part of the value we bring to the table.

Breaking Down Your Quote: What Are You Actually Paying For?

When a quote for a new machinery shed lands in your inbox, that final number can look pretty daunting. It’s a big investment. But once you understand what’s behind that figure, you start to see the true value.

Think of it like a good camp oven stew—the final result is only as good as the quality and quantity of everything you put in. A great shed isn’t just a kit of parts; it’s a full-blown construction project, and every single line item is crucial to getting it right.

To get our bearings, let’s look at the typical price points for different-sized machinery sheds across NSW.

As you can see, the price jumps significantly as you go up in size. That’s not just because of the extra steel; it’s also the bigger foundations, the extra labour, and everything else that scales up with it. Let's peel back the layers of a typical quote and see where every dollar really goes.

The Shed Kit and Materials

This is what most people picture when thinking about machinery sheds prices, but it's only one piece of the puzzle. The kit itself includes all the structural steel, the purlins and girts, and the cladding that keeps the weather out.

We’re uncompromising on this front. We only use high-tensile, Australian-made steel and genuine Colorbond for cladding because it’s been engineered to handle the harsh NSW sun, dust, and downpours for decades. You might save a few dollars upfront with cheaper imported steel, but it often leads to premature rust and fading, costing you a lot more in the long run.

Your material cost covers:

- Structural Frame: The main columns and trusses that form the backbone of your shed.

- Purlins and Girts: The secondary framing that the roof and wall sheeting attaches to.

- Cladding: Your choice of Colorbond sheeting for the roof and walls.

- Fasteners and Fixings: Every last nut, bolt, screw, and bracket, all properly engineered for strength.

Skilled Labour and Construction

A pile of steel doesn't put itself together. The labour cost covers our experienced crew—the hands on the ground needed to erect the structure safely, efficiently, and to Australian Standards.

This is about more than just bolting parts together. It’s precision work that ensures your shed is perfectly plumb, square, and structurally sound for a lifetime. Our teams have spent years building in rural environments, so they know how to work with the land, not against it.

Site Preparation and Earthworks

Before a single piece of steel goes up, the site itself has to be right. This is an absolutely critical step that guarantees a stable and long-lasting foundation for your shed.

Site prep usually involves:

- Clearing and Levelling: Getting rid of any vegetation and creating a perfectly flat pad.

- Cut and Fill: Moving earth around to build up low spots and cut down high ones.

- Compaction: Making sure the ground is rock-solid and won't sink or shift over time.

A poorly prepared site can cause major structural headaches down the track, which makes professional earthworks a non-negotiable part of the process.

Foundations: Concrete Slab and Footings

The concrete slab and footings are the literal foundation of your shed. The engineering here is dictated by your soil type, the size of the shed, and the weight of the machinery you plan to park inside.

A properly poured slab prevents cracking, gives you a durable work surface, and anchors the whole structure securely to the ground. This line item on your quote covers the concrete itself, the reinforcing steel, formwork, and the skilled concreters who pour and finish it to a professional standard.

Your shed is only as strong as its foundation. Skimping on concrete is one of the most common—and costly—mistakes you can make. It’s the anchor that holds your entire investment steady against wind, weather, and time.

Delivery and Logistics to Remote Sites

Getting tonnes of steel, concrete, and equipment out to a remote property is a massive logistical exercise. It’s where a lot of companies come unstuck, hitting you with hefty fees for difficult access. This is where we’ve invested heavily to be different.

We run a specialised 10-tonne 4×4 truck purpose-built for the challenges of rural NSW. This rig allows us to get all the labour, materials, and equipment to even the most isolated properties around Bourke, Walgett, and Broken Hill.

Whether it’s navigating muddy black soil plains or crossing a creek after a downpour, our truck gets us where we need to be, when we need to be there—without the crazy transport costs others might charge. This capability is core to how we deliver value and keep your project on track, no matter how far off the beaten path you are.

What Really Drives Your Final Shed Price?

Ever wondered why two machinery sheds of the exact same size can end up with wildly different price tags? The answer isn't just about the steel. It's all about the unique character of your land and the specific requirements of your project. Getting a handle on these variables is the key to managing your budget and making sure your new shed is built to last.

The final number on your quote is shaped by much more than the shed kit itself. Things like how easy it is to get to your site, the type of soil you're building on, how exposed you are to the wind, and your choice of materials can all have a major impact on the total cost. Let's break down the main factors that will determine what you ultimately pay.

Site Accessibility And Logistics

Getting the crew, materials, and heavy equipment to your build site is one of the biggest logistical puzzles, especially out here in rural New South Wales. If your property has easy, all-weather road access, things are pretty straightforward. But a remote block with unsealed tracks, creek crossings, or black soil plains that turn to a bog after a bit of rain? That's a different story.

Many builders will slap on hefty fees to deal with these challenges. This is where we do things differently at Awesim. We’ve invested in our own purpose-built 10 tonne 4×4 truck, designed specifically to bring materials and supplies to the most remote properties. This bit of kit allows us to bring in labour, materials, and equipment where and when it's needed the most across NSW. It means we can handle tricky access efficiently, which keeps your transport costs predictable and the whole project on track.

Soil Type And Foundation Engineering

The ground your shed sits on is just as crucial as the steel frame itself. Different soil types have completely different abilities to bear weight, and this directly affects the engineering—and the cost—of your concrete foundations.

- Stable Clay or Rock: If you're building on solid ground, a standard slab and footing design will likely do the job, which is the most cost-effective option.

- Reactive or Sandy Soil: On the other hand, looser or more reactive soils need deeper, more heavily reinforced footings to stop the slab from shifting, cracking, or sinking over time. Naturally, this extra engineering and concrete work will add to the price.

A professional soil test is often the first, and smartest, step to ensure your shed’s foundation is designed properly for the long haul.

Wind Rating And Structural Integrity

Where your property is located determines its wind rating, a critical factor that dictates just how strong your shed's frame needs to be. A shed tucked away in a sheltered valley near Tamworth will face very different wind loads compared to one on an exposed hilltop near the coast.

Complying with the correct AS/NZS 1170.2 wind rating is non-negotiable. It’s what ensures your shed can stand up to the strongest winds it's ever likely to encounter, protecting your gear and keeping everyone safe. A higher wind rating demands a heavier steel frame and more robust connections, which, of course, adds to the material cost.

Material Choice And Shed Complexity

The materials you select and the complexity of your design play a massive part in the final price. While it can be tempting to go for cheaper, imported steel, genuine Australian-made Colorbond steel offers far superior durability against our harsh NSW climate. It’s an investment that saves you a lot of money on maintenance and repairs down the line.

Your budget will also be influenced by custom features:

- Bay Sizes: If you need non-standard bay widths to fit specific machinery, you might need heavier structural steel.

- Door Types: Large roller doors, sliding doors, and personal access doors all come at different price points.

- Enclosed vs Open: Fully enclosed bays with wall cladding will cost more than simple open-front designs.

- Extras: Things like insulation, skylights, ventilation, or internal partition walls will add to the final cost but can make the shed far more functional. You can explore some of these options in our guide to farm shed design.

Don't forget that preparing the site is a vital first step. Clearing trees and other obstacles needs to be factored in, and using a tree removal cost calculator can help you budget for this part of the job.

With Australian steel prices starting to stabilise, the cost of farm sheds across New South Wales remains a hot topic. All in, you can expect total project expenses to range anywhere from $50,000 to $270,000. For farmers in places like Armidale or Parkes, a mid-sized machinery shed often comes in around $175-$280 per square metre—a sound investment to protect vital equipment from the region's notorious dust storms and floods.

Real-World Shed Quotes For NSW Properties

It’s one thing to talk about costs in theory, but seeing how the numbers come together for actual projects is where the rubber really meets the road. To give you a clearer picture of how machinery shed prices work for different setups, we've outlined a couple of sample quotes based on common jobs we handle across rural New South Wales.

These examples show you exactly how factors like size, features, and location can shape the final investment. We believe in total transparency, so we've broken them down line by line, just like a real proposal from Awesim Building & Construction. You'll see exactly where every dollar goes.

Sample Quote Comparison For NSW Machinery Sheds

Let's look at two distinct projects. The first is a classic, fully enclosed shed perfect for a mixed-farming operation in the Central West. The second is a much larger, open-front design built for a broadacre cropping enterprise on the challenging black soil plains.

| Cost Item | Example 1: 24x15m Enclosed Shed (Dubbo) | Example 2: 40x21m Open-Front Shed (Moree) |

|---|---|---|

| Shed Kit & Materials | $52,000 | $78,000 |

| Labour & Construction | $27,500 | $38,000 |

| Concrete Slab & Footings | $29,000 | $45,000 |

| Site Preparation | $6,500 | $9,000 |

| Council Approval & Fees | $3,000 | $4,500 |

| Total Estimated Price (inc. GST) | $118,000 | $174,500 |

The difference in the bottom line isn't just about size. The Moree project needs a significantly beefier foundation to handle the reactive black soil, adding thousands to the concrete and engineering costs. This is a perfect example of why a one-size-fits-all price just doesn't exist.

A crucial takeaway here is how much site conditions can impact the final price. The additional engineering and concrete needed for a stable foundation in places like Moree represent a significant, yet non-negotiable, part of the investment.

A Closer Look At The Details

Let’s break down what's driving those numbers for each project.

H3: Quote 1: Mid-Sized Enclosed Shed Near Dubbo

This is a bread-and-butter shed for a mixed farming operation. It needs to be secure enough to protect expensive gear from both the weather and potential thieves. The design is all about practical, robust functionality.

- Project Scope: A 24m x 15m x 5m fully enclosed machinery shed.

- Key Features: Three large roller doors, a personal access door, and full Colorbond cladding.

- Site Conditions: A relatively flat block with stable clay soil, meaning standard earthworks and foundations get the job done.

H3: Quote 2: Large Open-Front Shed Near Moree

For a big cropping enterprise, the game changes. The main priority is quick, easy access for massive gear like harvesters and air seeders. Here, the design focuses on wide-open space and height, with a secure workshop bay tucked in.

- Project Scope: A huge 40m x 21m x 6.5m open-front shed with one fully enclosed 7m bay.

- Key Features: Extra-wide 10m bays for harvester access and a taller 6.5m eave height.

- Site Conditions: Reactive black soil that demands more extensive foundation engineering and a thicker, more heavily reinforced slab.

These figures really underscore the importance of getting a detailed, site-specific quote. Industry data backs this up, too. Recent pricing for a large 12m x 24m x 5m commercial shed kit—a good starting point for machinery storage—was quoted at $108,280 delivered, including GST.

That 288sqm structure in BlueScope steel was engineered for Australian wind regions, which shows how the kit price alone makes up a massive chunk of the total cost. You can often explore commercial shed kit prices online to get a baseline, but remember it’s only one piece of the puzzle.

Investing for the Long Haul: Getting Real Value from Your Shed

When you start looking at machinery shed prices, it's easy to get fixated on the number at the bottom of the quote. But let's be honest, the cheapest option upfront is rarely the best investment for a working farm. Real value isn’t about the lowest price tag; it’s about decades of reliable service, minimal upkeep, and making your entire operation run a bit smoother.

Thinking of your new shed as a long-term asset changes the question from "How much does it cost?" to "What is it actually worth?". A properly built, fully compliant shed is far more than just a roof over your gear. It's a vital piece of farm infrastructure that protects your most expensive equipment, adds real, tangible value to your property, and is built to serve your family for generations.

Built for the NSW Climate, Not Just for Today

The New South Wales climate doesn't mess around. From the scorching sun and dust storms out west to the salty, humid air and torrential rain on the coast, our weather will ruthlessly expose any weak link in a structure. This is precisely where investing in quality, Australian-made materials proves its worth, over and over again.

Sure, you might shave a few percentage points off the initial cost by using cheaper, imported steel, but that's a decision that almost always leads to expensive problems down the track. We only use high-tensile, Australian-made steel and genuine Colorbond because it’s been engineered from the ground up to handle these exact conditions, fighting off rust, fading, and corrosion for decades.

This commitment to quality really means three things for you:

- Lower Maintenance Bills: You won't be wasting your time or money on rust repairs, repainting jobs, or replacing flimsy components before their time.

- Serious Durability: Your shed will stand firm against whatever the elements throw at it, protecting the million-dollar assets you've got parked inside.

- Peace of Mind: There's a genuine sense of security that comes from knowing your structure is built to last. You just don't get that with a budget build.

A Partner in Building Resilient Farm Infrastructure

At Awesim, we're not just shed builders. We see ourselves as your partners in developing strong, valuable farm infrastructure that lasts. With 35 years of hands-on experience in rural construction, we know what a successful project looks like: it’s delivered on schedule, on budget, and built to stand the test of time.

This partnership approach means we take care of all the details, from the first sketch to the final sign-off. We handle the council approvals, the engineering specs, and the often-tricky logistics of getting materials and crew to your site—even if it's kilometres down a dirt road.

Given that a substantial machinery shed represents a significant piece of commercial real estate, securing the right type of commercial real estate loan is a key part of long-term value. A well-built, compliant structure not only serves your operational needs but also strengthens your farm's balance sheet, making it a sound financial asset.

Our experience helps your project steer clear of the common traps and delays, ensuring a smooth run and a finished product that adds immediate, lasting value to your property. By focusing on quality from the slab up, we help you make an investment that pays you back for years to come—protecting your machinery, streamlining your workflow, and ultimately strengthening the future of your whole operation.

Getting A Custom Machinery Shed For Your Property

So, you've seen what goes into machinery shed prices, from the big-picture estimates right down to the nitty-gritty of a quote. The one thing that should be crystal clear is that the best projects are a smart balance between the initial outlay and the shed's long-term performance.

It's never just about the price tag. The real goal is a structure that fits your land, protects your gear, and stands up to the specific demands of your corner of New South Wales. This is exactly why a custom, site-specific design makes all the difference—it ensures every dollar spent is an investment in lasting value.

Your Simple Path to a Shed Proposal

We've made getting an accurate, obligation-free quote as straightforward as possible because we know you're busy. Our whole approach is built on understanding your needs first, so the proposal we give you is a true reflection of what your project actually involves.

It’s an easy process:

- Initial Chat: It all starts with a simple conversation. We’ll talk about what you're looking for—the size of the shed, the style you're after, and any special features you need.

- Site Assessment: We'll get into the details of your property, discussing things like site access, soil conditions, and exactly where the shed will go.

- Detailed Proposal: You'll get a clear, itemised quote that breaks down every cost. No surprises, just a complete picture of what you're paying for.

Navigating local rules is a big part of any build. For a deeper dive, have a look at our guide on whether you need council approval for a shed.

We Come To You, No Matter Where You Are

Building in rural NSW isn't for the faint-hearted. Getting crews and materials out to remote properties is a logistical puzzle we've spent years perfecting, so you can count on a smooth build no matter where you are on the map.

Remember, with our dedicated 10-tonne 4×4 truck, we bring the entire project to you. From the black soil plains of Nyngan to the rugged tracks near the border, we're equipped to handle the unique challenges of building in rural NSW. This allows us to bring in labour, materials, and equipment where and when it's needed the most. This is our commitment to providing a seamless building experience, no matter how far off the bitumen you are.

Your Machinery Shed Questions Answered

When you're looking to invest in a new machinery shed, a few key questions always come up. Getting straight answers is the first step to understanding what's involved and making sure you're getting genuine value for your money. Here are the most common queries we get from landowners across NSW.

How Long Does Building A Machinery Shed Take?

The whole process splits into two main parts. First, you've got the planning and approvals, which typically takes anywhere from 4 to 8 weeks for the local council to sign off on everything.

Once we have the green light, the on-site work begins. Actually preparing the ground and putting the shed up usually takes another 2 to 6 weeks, though this can change depending on how big and complex your build is. We handle the lot, so you're not left chasing councils or contractors.

Do I Really Need Council Approval For A Farm Shed?

The short answer is yes. For just about any machinery shed in New South Wales, you'll need to get the proper council approvals. It might feel like a bit of red tape, but it’s there for a good reason – to make sure your shed is safe, structurally sound, and meets all the right building codes.

Don't worry, this is all part of our service. Our team manages all the paperwork, from lodging the applications to submitting the plans and engineering specs. We make sure everything is up to Australian Standards, taking the hassle completely off your plate.

Because we manage your project from the ground up, we guarantee the design, engineering, and materials all work together perfectly for your specific site. This approach avoids costly mistakes and ensures your shed is built properly from day one.

Can I Save Money By Buying My Own Shed Kit?

It can be tempting to buy a kit yourself to try and save a few dollars, but we've found our complete end-to-end service delivers far better value in the long run. When we manage the whole project, we ensure every single component is right for the job.

This integrated process sidesteps the expensive problems that often pop up with off-the-shelf kits, like finding out the wind rating is wrong for your area or that the foundation design doesn't suit your soil.

Ready to build a shed that's designed for your property and built to last? Contact Awesim Building Contractors for a detailed, no-obligation quote and discover how we deliver superior value and a seamless construction experience across rural NSW. Visit us at https://awesim.au.